We are excited to announce the new RIDGID Pipe Patching kits. Known for their ingenuity, the developers at RIDGID made their systems for CIPP (cured-in-place pipe) patching. CIPP is a method used worldwide to repair broken or damaged pipe sections. This method is known for its quick return on investment, easy learning curve, effectiveness, and reliability, often lasting for decades. RIDGID provides everything needed to get started.

What is CIPP?

CIPP (cured-in-place pipe) patching is a practice of efficiently repairing damaged lines. It’s practical and cost-effective. CIPP is quickly becoming a frontrunner in trenchless pipe rehabilitation. Here is the process, more or less:

- Using a camera, inspect the damaged pipe, clear away any blockage and clean the line of debris.

- Navigate the Packer with the patch to the patch location, inflate the packer, and let the resin set for its set time.

- After the resin has cured, deflate the packer and remove it.

Work time can be as little as fifteen minutes but requires a minimum of 90 minutes for the resin to set. CIPP can be a profitable standalone business or a significant addition to businesses already offering trenchless rehabilitation.

What systems and kits does RIDGID offer?

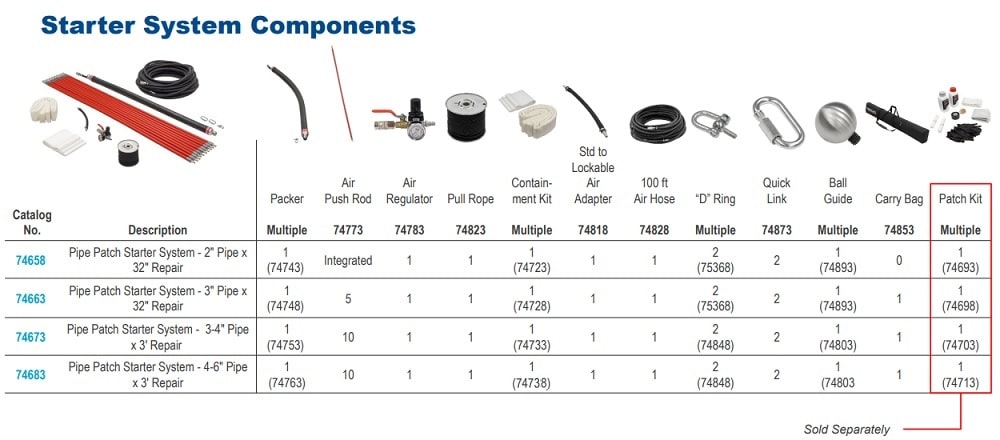

RIDGID is offering four starter systems and four patch kits. The difference between a starter system and a patch kit is a starter kit has all the tools needed to perform the patch job, including the packer. While the patch kit includes the resin and the packer sleeves, they are sold separately, but each patch kit corresponds to a starter system based on pipe size. Ridgid’s smallest pipe patch system is for a 2-inch pipe with options up to 6 inches.

Starter System

There are four different options for starter kits:

We are excited to announce the new Moen eToilets with bidet seats here at PlumbersStock. We’ve got the 2-series, 3-series, and 5-series options, which come with tons of features (keep reading for details).

We are excited to announce the new Moen eToilets with bidet seats here at PlumbersStock. We’ve got the 2-series, 3-series, and 5-series options, which come with tons of features (keep reading for details).  We are excited to announce the release of new Moen eBidet seat attachments. There are three models from which to choose.

We are excited to announce the release of new Moen eBidet seat attachments. There are three models from which to choose.

We are excited to introduce the new Moen smart kitchen faucets that are additions to the Nio, Paterson, Sinema, and Weymouth collections.

We are excited to introduce the new Moen smart kitchen faucets that are additions to the Nio, Paterson, Sinema, and Weymouth collections.  You can read about the original

You can read about the original  We are excited to announce

We are excited to announce  Quality

Quality  We are excited to announce the new Toro Tempus sprinkler controller. As you probably know,

We are excited to announce the new Toro Tempus sprinkler controller. As you probably know,  We are excited to announce an amazing portable power supply solution. The new Milwaukee M18 carry-on power supply is a versatile 15 amp, hassle-free option. This is no surprise, given that

We are excited to announce an amazing portable power supply solution. The new Milwaukee M18 carry-on power supply is a versatile 15 amp, hassle-free option. This is no surprise, given that

The summer of 2022 brings us exciting news about changes to one of our favorite

The summer of 2022 brings us exciting news about changes to one of our favorite