Are you neglecting your annual boiler inspection? This crucial procedure not only ensures your boiler operates efficiently but also helps prevent costly leaks and potential failures. In this comprehensive guide, you’ll discover the importance of regular boiler maintenance, learn effective preparation steps, and follow a detailed step-by-step inspection process. By understanding these essential procedures, you'll minimize breakdowns and extend the life of your boiler, all while navigating compliance standards that keep your home safe. Avoid the pitfalls of unpaid attention—let’s dive into how you can keep your boiler running smoothly.

Understanding the Importance of Annual Boiler Inspections

Annual boiler inspections are crucial for ensuring safety within your facility and for the personnel working there. By regularly checking components like the relief valve and conducting boiler blowdown procedures, you can significantly prolong the lifespan of your boiler system. Additionally, early detection of potential issues can reduce operational costs. These inspections also help you meet regulatory compliance with standards such as the ASME Boiler and Pressure Vessel Code, protecting against hazards like carbon monoxide emissions.

Ensuring Safety for Your Facility and Personnel

Your facility's safety hinges on the proper functioning of your HVAC Supplies boiler system. Annual inspections help identify potential failures in components like the pump, ensuring they are operating efficiently. By addressing these issues promptly, you significantly reduce the risk of accidents that could endanger personnel and cause costly disruptions in construction projects.

Energy efficiency is another critical factor in maintaining a safe working environment. Regular boiler inspections help ensure that your condensing boiler is working optimally, minimizing energy waste and lowering utility costs. A well-maintained system also reduces the likelihood of unexpected failures that could lead to hazardous conditions, ensuring your operations run smoothly.

Incorporating annual inspections into your facility's maintenance routine not only enhances safety but also fosters a culture of proactive care among staff. Educating your team about the importance of these inspections can lead to improved practices that prioritize the well-being of everyone on-site. By committing to routine evaluations, you create a safer environment and demonstrate a responsible approach to managing your facility’s infrastructure.

Prolonging the Lifespan of Your Boiler System

Prolonging the lifespan of your boiler system is essential for both safety and efficiency. Annual inspections by a qualified inspector are key for identifying and resolving issues such as corrosion or leaks in the tank before they escalate. Regular maintenance actions, including conducting a hydrostatic test, can ensure that your boiler operates safely and meets the required pressure standards, thus preventing unexpected breakdowns.

Your chimney is critical in ensuring exhaust gases are properly vented, reducing potential hazards. A well-maintained chimney system not only enhances the efficiency of your boiler but also mitigates the risk of harmful emissions such as carbon monoxide. Ensuring that the chimney is clear and functional can significantly extend the life of your boiler by preventing overheating and associated damages.

It’s important to address any potential asbestos issues in older boiler systems. If your facility operates a vintage boiler, having an inspector evaluate for asbestos during the annual inspection is crucial for both safety and compliance. Understanding these risks and addressing them promptly fosters a proactive approach to maintenance, safeguarding both your equipment and your personnel. Here’s a quick overview of key maintenance steps to prolong your boiler’s lifespan:

- Schedule annual inspections with a certified inspector.

- Conduct a hydrostatic test to check for leaks.

- Maintain the chimney to ensure proper venting.

- Evaluate and address any asbestos concerns.

Reducing Operational Costs With Early Detection

By addressing issues during annual boiler inspections, you can significantly reduce operational costs. Early detection of problems such as leaks or flue blockages helps you avoid major repairs or replacements later on. This proactive approach not only enhances safety but also ensures compliance with building codes set forth by the American Society of Mechanical Engineers.

Moreover, when small faults are caught and rectified promptly, they prevent costly interruptions in your work processes. For example, a minor issue with a flue could lead to dangerous conditions like carbon monoxide buildup or even flooding if left unchecked. By maintaining regular inspections, you safeguard your investments and avoid unexpected expenses down the line.

Integrating an early detection strategy into your maintenance routine is not just about saving money. It’s about protecting your facility and personnel from potential hazards that could arise from ignored boiler issues. Consider the long-term benefits of preventative maintenance: it’s an investment in the reliability, efficiency, and safety of your boiler system:

- Schedule timely annual inspections.

- Identify minor issues before they escalate.

- Ensure compliance with safety regulations.

- Reduce the risk of costly repairs and operational disruptions.

Meeting Regulatory Compliance and Standards

Meeting regulatory compliance and standards is vital for any facility utilizing a boiler system. Regular inspections ensure that key components, like sensors and combustion systems, function effectively, thereby reducing risks associated with flue gas emissions and corrosion. Compliance not only protects your investment but also ensures the safety of the personnel working within your facility.

Understanding the regulatory requirements of your specific boiler system helps you to remain proactive. For instance, regulations often include standards related to coal use, emissions, and maintenance practices. Failing to comply with these standards can lead to hefty fines or operational shutdowns, which underline the importance of staying informed and prepared.

Incorporating annual inspections as a routine practice allows you to address compliance issues before they escalate. Regular maintenance checks can identify problems like corrosion in boiler components or malfunctions in combustion that could violate safety standards. By prioritizing these inspections, you ensure that your operations remain efficient and within legal guidelines:

- Assess sensor functionality to prevent hazardous conditions.

- Monitor for signs of corrosion affecting system integrity.

- Evaluate flue gas emissions to ensure compliance.

- Maintain proper combustion practices to reduce operational risks.

Preparing Effectively for Your Boiler Inspection

Scheduling your boiler inspection at an optimal time sets the stage for a smooth process. Organizing essential documentation, including service records and safety valve certifications, is crucial for a thorough evaluation. Notify staff to ensure facility access and consider performing preliminary cleaning and maintenance around radiators and water heating systems. These steps will enhance the effectiveness of the inspection.

With these preparations, you create an environment conducive to identifying potential issues like pressure inconsistencies or lubricant needs during the inspection. This proactive approach significantly contributes to the overall safety and efficiency of your boiler system.

Scheduling the Inspection at an Optimal Time

Scheduling your boiler inspection at the right time is essential for maximizing efficiency and compliance with regulations. Ideally, you should plan the inspection during a period when your facility is less active, allowing for unobstructed access to elements like ventilation and gaskets. This timing helps the inspector perform a thorough check without interference, ensuring all components are assessed comprehensively.

Consider the seasonal demands on your boiler system. For instance, scheduling inspections before peak usage times can prevent operational disruptions and ensure that any necessary repairs or adjustments are made in advance. Early scheduling allows you to address issues related to carbon emissions or flue safety, which can be critical during high-demand periods.

Additionally, it’s vital to be aware of any associated fees that may apply when scheduling your inspection. Different companies may have varying fee structures based on the schedule or type of inspection required. By confirming the costs and discussing your needs upfront, you can avoid unexpected charges and ensure a smooth process that aligns with your maintenance budget:

- Plan inspections during off-peak times for best access.

- Monitor seasonal usage patterns to schedule strategically.

- Verify inspection fees and associated costs in advance.

Organizing Essential Documentation and Records

To ensure a successful boiler inspection, it is essential to gather all necessary documentation and records beforehand. This includes previous inspection reports, maintenance records, and any licenses held by the technicians performing the inspection. Organizing these documents will not only provide valuable insights into your boiler's history but also streamline the inspection process.

Creating a comprehensive checklist is a practical approach to managing documentation for your annual boiler inspection. This checklist should include items such as valve certifications, repair records, and compliance documents. Having these records organized will help the inspector assess the condition of your system more efficiently and address any potential concerns swiftly.

Make it a practice to keep all documentation up to date-and readily accessible. By maintaining complete and accessible records, you empower the inspector to conduct a thorough evaluation of your boiler system. This proactive approach not only reinforces compliance with safety standards but also enhances the overall safety and reliability of your facility's heating system:

- Collect maintenance records and previous inspection reports.

- Create a detailed checklist of required documents.

- Ensure all records are kept up to date and easily accessible.

Notifying Staff and Ensuring Facility Access

Notifying your staff ahead of the annual boiler inspection is essential for ensuring smooth operations. Communicate the inspection date and time clearly to all relevant personnel. This proactive measure allows them to prepare the area around the boiler and ensure that access is unrestricted, facilitating a thorough evaluation of critical components such as the sight glass and flame sensors.

Additionally, it's important to inform your team about any specific preparations or precautions needed during the inspection process. For example, if your boiler runs on natural gas, staff should be aware not to alter any settings or procedures leading up to the inspection. Keeping everyone informed reduces the risk of operational interruptions and ensures safety protocols are maintained.

Make sure that staff members understand the significance of the inspection and what it entails. Explain that the inspector will evaluate everything from the condenser to safety devices, and a well-prepared facility enhances the possibility of identifying any issues before they become serious problems. This approach fosters an atmosphere of responsibility and awareness, ultimately contributing to the safety and reliability of your boiler system.

Performing Preliminary Cleaning and Maintenance

Performing preliminary cleaning and maintenance before your boiler inspection is essential for enhancing the inspection process. You should begin by checking and cleaning the heat exchanger, as accumulated debris can impede efficiency and hinder the inspector’s ability to assess its condition thoroughly. Ensuring that all surfaces around the boiler, including pipes and fittings, are free from dust and oil will help present a clear view of the system's operational state.

Additionally, inspect your storage tank to avoid any surprises during the inspection. Remove any excess oil or residues that may have built up over time, as this can affect the performance of the pressure vessel. Taking the time to maintain these components not only follows good practices but also supports the longevity and reliability of your boiler system.

Make sure to also address any visible leaks or signs of wear around the pipes and connections prior to the inspector's visit. Tightening loose fittings and replacing worn gaskets can prevent potential issues from escalating during the inspection. By being proactive and taking these steps, you foster a smooth inspection process that ultimately ensures the safety and efficiency of your boiler system:

- Clean the heat exchanger for optimal performance.

- Inspect and clean the storage tank to avoid operational issues.

- Check and maintain all pipes and connections for visible damage.

Step-by-Step Guide to Boiler Inspection Procedures

Begin your annual boiler inspection with a thorough external examination of components, followed by an internal inspection of the boiler itself. This includes testing crucial safety controls and emergency shutoffs to ensure functionality. Next, assess the overall performance and efficiency of your recovery boiler. Finally, compile your inspection findings and recommendations for maintenance or repairs, focusing on key HVAC Parts and supplies relevant to Radiant Heating and Cooling systems.

Conducting an External Examination of Components

When conducting an external examination of your boiler components, start by inspecting the condition of the insulation and piping. Look for any signs of wear, leaks, or corrosion that could indicate underlying issues. This initial assessment is crucial, as it allows you to catch minor problems before they escalate, ultimately safeguarding your boiler's efficiency and preventing costly repairs.

Next, you should check important elements such as the pressure relief valve and gauge, as well as the burner assembly. Ensure that these components operate smoothly and show no signs of malfunctions. A well-functioning pressure relief valve is essential for regulating your boiler’s pressure and preventing unsafe conditions.

Finally, the overall cleanliness of the external surfaces will be assessed. Remove any accumulated dirt or debris that could obstruct airflow or hinder proper heat transfer. Keeping the exterior clean not only promotes optimal performance but also supports safety by reducing the risks of overheating and other related hazards during operation.

Performing an Internal Inspection of the boiler

When performing an internal inspection of your boiler, begin by ensuring safety protocols are in place. This involves shutting down the boiler and allowing it to cool adequately before opening any access points. Inspecting key components such as the heat exchanger, boiler tubes, and combustion chamber is essential, as these areas are prone to wear and corrosion that can affect performance.

During the internal inspection, take note of any visible signs of damage, such as cracks or scaling within the heat exchanger. These issues can significantly impact the efficiency and reliability of your boiler system. By identifying these problems early, you can arrange for necessary repairs or replacements, preventing costly downtime and enhancing safety.

Finally, check the operational mechanisms, like the burner and fuel supply lines, to ensure they are functioning correctly. Regular monitoring of these components not only maintains optimal performance but also aligns with safety regulations. By prioritizing your boiler's internal inspection, you reinforce its reliability and assure compliance with the necessary standards:

- Shut down the boiler and ensure it has cooled.

- Inspect the heat exchanger and boiler tubes for damage.

- Examine the burner and fuel supply lines for proper operation.

Testing Safety Controls and Emergency Shutoffs

Testing safety controls and emergency shutoffs is a pivotal part of your annual boiler inspection. You should start by verifying the functionality of these controls to ensure that they react appropriately in emergency situations. Inadequate performance of these systems can lead to dangerous conditions, making your regular inspections essential for maintaining a safe environment.

During your inspection, pay particular attention to the calibration of safety controls. This involves checking that pressure and temperature limits are set correctly and respond in real-time to system changes. Regularly ensuring these controls function correctly not only enhances safety but also promotes efficient boiler operation, helping you avoid unforeseen breakdowns.

Additionally, robust testing of emergency shutoff systems provides an extra safety net for your operations. You should simulate various emergency conditions to confirm that these systems activate as intended. This proactive measure secures your facility and reinforces your commitment to safety, ultimately protecting both personnel and equipment from potential hazards.

Assessing Boiler Performance and Efficiency

Assessing boiler performance and efficiency is critical for maintaining a safe and cost-effective heating system. You should regularly monitor essential metrics such as temperature, pressure, and flow rates during your inspections. By gathering this data, you can better understand how efficiently your boiler operates, identifying potential areas for improvement and ensuring compliance with performance standards.

During the boiler inspection, take note of any discrepancies in the expected performance levels. For instance, if the pressure exceeds established limits, it may indicate a malfunctioning component or the need for adjustments. Analyzing these factors allows you to implement corrective measures that enhance boiler efficiency, which can lead to significant energy savings and reduced operational costs in the long run.

Additionally, understanding fuel usage patterns is essential for assessing overall efficiency. You can calculate the efficiency ratio by comparing the input energy against the output energy of the steam or hot water produced. This way, you pinpoint any inefficiencies, allowing you to make necessary adjustments, optimize performance, and enhance your facility's operational reliability:

- Monitor essential performance metrics during inspections.

- Identify discrepancies in expected pressure and temperature.

- Calculate efficiency ratios for informed adjustments.

Compiling Inspection Findings and Recommendations

After completing your annual boiler inspection, compiling your findings is vital for maintaining an efficient and safe heating system. Clearly documenting any identified issues, the condition of key components, and the performance metrics observed during the inspection creates a comprehensive record that serves as a valuable reference. This organized documentation not only assists in strategizing repairs and maintenance but also enhances communication with your team and any external service providers.

When outlining your recommendations, it is essential to prioritize actions based on the severity of the issues identified. For instance, if you find a malfunctioning safety valve, it should be addressed immediately to prevent potential risks. Providing clear recommendations on repair timelines and further inspections can guide your team in making informed decisions and ensuring compliance with safety regulations.

Moreover, incorporating a follow-up plan in your compiled findings fosters accountability and supports ongoing maintenance. By scheduling future inspections or maintenance tasks based on your recommendations, you help ensure that your boiler system operates efficiently and meets safety standards continuously. Regularly revisiting your inspection findings and implementing recommended actions will ultimately safeguard your facility and optimize your boiler's performance.

Identifying and Addressing Common Inspection Findings

During your annual boiler inspection, it's essential to identify common findings that may impact the system's efficiency and safety. You will want to focus on detecting signs of corrosion and metal fatigue, identifying leaks and structural cracks, managing scale build-up and deposits, resolving combustion and burner issues, and replacing or repairing faulty components. Each of these areas is crucial for maintaining optimal boiler performance and ensuring a safe operating environment.

Detecting Signs of Corrosion and Metal Fatigue

Detecting signs of corrosion and metal fatigue during your annual boiler inspection is vital for maintaining safety and efficiency. Look for visible rust, pitting, or discolored areas on metal surfaces, as these indicators often signify that the material is deteriorating. Additionally, check for flaking paint or protective coatings, which can expose metal components to moisture and accelerate corrosion.

Conducting regular inspections helps you identify these critical issues before they result in significant failures. Pay particular attention to welds and joints, as these areas often bear the brunt of stress and are prone to fatigue. If you notice any abnormalities, make sure to document your findings and consider scheduling a follow-up with a qualified technician to address these concerns.

By recognizing and addressing corrosion and metal fatigue early, you can prevent costly repairs and ensure your boiler system operates smoothly. Regular evaluations not only extend the lifespan of your equipment but also enhance the overall safety of your facility. Consider the following key actions when inspecting for these common issues:

- Inspect metal surfaces for signs of rust, pitting, or discoloration.

- Examine welds and joints closely for signs of fatigue.

- Document findings and schedule timely repairs with a qualified technician.

Identifying Leaks and Structural Cracks

Identifying leaks and structural cracks during your annual boiler inspection is critical for maintaining safety and operational efficiency. During your inspection, closely examine joints, seams, and connection points for any signs of moisture or water stains, which can indicate not only leaks but also potential structural weaknesses in the boiler system. Addressing these issues promptly can prevent larger failures and costly repairs down the line.

Another area to scrutinize is the boiler's pressure vessel, where structural integrity is paramount. Look for any visible cracks or deformities in the metal that could signify serious underlying problems. Failing to detect these issues early can lead to unsafe operating conditions and may violate safety regulations, so maintaining vigilance during inspections is essential for your facility's well-being.

In practice, employing pressure testing in conjunction with your visual inspections can provide an added layer of assurance against leaks. By systematically monitoring pressure levels, you can identify discrepancies that may not be visible on the surface. Implementing such proactive measures not only ensures compliance with safety standards but also enhances the reliability and longevity of your boiler system.

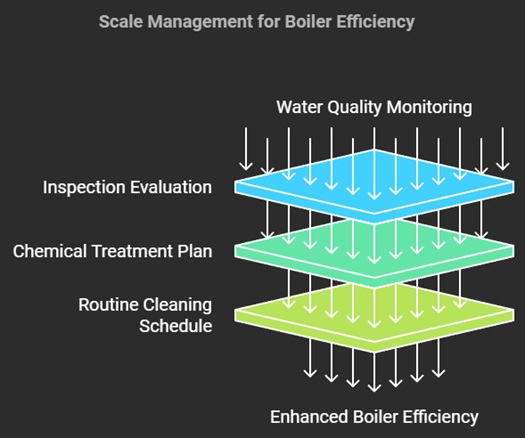

Managing Scale Build-Up and Deposits

Managing scale build-up and deposits in your boiler system is critical for maintaining efficiency and safety. Scale can lead to reduced heat transfer and increased energy costs, compromising your boiler's performance. Regular monitoring and treatment of water quality help minimize scale formation, ensuring your system operates efficiently.

During an annual inspection, you should assess the condition of your water treatment systems. Implementing a chemical treatment plan may be necessary to prevent scale deposits in the heat exchanger and other critical components. Keeping the system clean and free from contaminants not only promotes effective heat exchange but also enhances the longevity of your boiler.

To effectively manage scale build-up, consider conducting routine manual cleanings and chemical descaling based on your facility's water quality and operational needs. Establishing a regular maintenance schedule will help you avoid major issues down the line. Remember, addressing scale accumulation proactively can lead to improved efficiency and reduced operational costs:

- Monitor water quality regularly to detect scale issues early.

- Evaluate water treatment systems during inspections.

- Implement a routine cleaning schedule to manage deposits.

Resolving Combustion and Burner Issues

Resolving combustion and burner issues is essential for maintaining efficient boiler operations and ensuring safety. During your annual inspection, you'll want to carefully assess the combustion chamber and burner assembly for any signs of irregularities. A properly functioning burner should deliver a stable flame and efficient fuel consumption, both of which are critical for optimal performance and energy savings.

Common combustion problems include uneven flame distribution and excessive emissions, which not only signify inefficiencies but could also pose safety hazards. If you notice a yellow or flickering flame instead of a solid blue flame, this may indicate incomplete combustion, suggesting a need for adjustments in air-to-fuel ratios or cleaning of the burner components. Addressing these issues during your inspection can help you avoid costly repairs and downtime.

Furthermore, monitoring carbon monoxide levels during the inspection is crucial for ensuring a safe working environment. High levels of carbon monoxide not only indicate poor burner performance but also present serious health risks. Regular maintenance and timely repairs can improve combustion efficiency, reduce harmful emissions, and enhance the overall functionality of your boiler system, allowing your facility to operate smoothly and safely.

Replacing or Repairing Faulty Components

If you identify faulty components during your annual boiler inspection, addressing them promptly is essential for maintaining the safety and efficiency of the system. Common issues include malfunctioning safety valves, burnt-out burners, or deteriorating pressure gauges. Replacing or repairing these faulty components can safeguard your facility against operational hazards and extend the lifespan of your boiler.

For example, if the pressure relief valve shows signs of wear, replacing it immediately can prevent dangerous pressure buildups. In contrast, if you find minor leaks around fittings, you might only need to tighten connections or replace gaskets instead of undertaking a complete replacement. Being proactive with these repairs not only reduces the risk of equipment failure but also keeps your maintenance costs manageable.

To effectively manage the replacement or repair of faulty components, keep a schedule of inspections and track the condition of critical parts. Documenting maintenance history will help you anticipate future repairs and budget accordingly. By taking a methodical approach to managing your boiler's functionality, you can prevent unexpected downtime and ensure your systems operate smoothly:

- Identify faulty components promptly during inspections.

- Repair minor issues like leaks or faulty gauges without replacement.

- Replace critical parts like pressure relief valves to ensure safety.

- Maintain a record of inspections and repairs for future reference.

Maintaining boiler Efficiency Between Annual Inspections

To maintain boiler efficiency between annual inspections, it's essential to implement a regular maintenance schedule and continuously monitor key performance indicators. Training your staff on proper operation procedures ensures safety and reliability. Additionally, utilizing advanced monitoring technologies can provide real-time data for proactive adjustments, further enhancing system performance and longevity.

Implementing a Regular Maintenance Schedule

Implementing a regular maintenance schedule for your boiler system is essential for maintaining efficiency between annual inspections. Establishing a routine helps identify minor issues before they escalate, safeguarding your investment and ensuring reliable performance. You should plan maintenance tasks such as checking pressure levels, inspecting safety controls, and cleaning components at consistent intervals to promote optimal operation.

An effective maintenance schedule should be tailored to your facility's specific needs and usage patterns. For instance, if your boiler experiences heavy use during colder months, scheduling more frequent checks leading up to and during peak usage can prevent unexpected breakdowns. Additionally, training your staff on proper operation procedures plays a vital role in maintaining boiler efficiency, ensuring they understand how to identify potential problems early.

Documenting all maintenance activities is also crucial for ongoing efficiency. By keeping accurate records of inspections, repairs, and performance metrics, you create a reliable reference that can inform future maintenance decisions. This practice not only enhances accountability but also supports your long-term strategy for maintaining a safe and efficient boiler system:

- Schedule routine check-ups for key components.

- Train staff on operational best practices.

- Document and review maintenance activities regularly.

Monitoring Key Performance Indicators

Monitoring key performance indicators (KPIs) is essential for maintaining the efficiency of your boiler system between annual inspections. By tracking metrics such as fuel consumption, steam output, and operating pressure, you can gain valuable insights into your boiler's performance. This data allows you to identify trends and potential issues early on, ensuring your system operates reliably and remains compliant with safety regulations.

Regularly assessing KPIs empowers you to make informed decisions regarding maintenance and operational adjustments. For instance, if you notice increased fuel usage without a corresponding increase in steam production, it may indicate a need for burner adjustments or servicing. Addressing these discrepancies promptly not only enhances efficiency but also contributes to a safer work environment by minimizing risks associated with boiler malfunctions.

Additionally, establishing baseline performance metrics for your specific boiler model will help you identify deviations that require immediate attention. By comparing real-time data against these standards, you can proactively address inefficiencies and avoid costly downtime. Adopting this proactive approach to monitoring your boiler’s key performance indicators ensures that you maintain optimal performance levels and ultimately extend the lifetime of your boiler system.

Training Staff on Proper Operation Procedures

Training your staff on proper operation procedures is a key aspect of maintaining boiler efficiency between annual inspections. Equip your team with the knowledge to operate the boiler safely and efficiently, which directly impacts performance and operational longevity. Conduct regular training sessions focusing on the operational limits, emergency shutoff procedures, and daily checks they should perform to ensure everything is functioning correctly.

Encourage your staff to be vigilant about their roles concerning the boiler system. Simple actions, such as checking gauges and monitoring fuel consumption, can identify issues early before they lead to costly repairs or unsafe conditions. You can also provide hands-on training opportunities that reinforce theoretical knowledge and help staff develop practical skills critical for the safe operation of the boiler.

To further support your training efforts, consider creating easy-to-follow manuals or checklists that outline the proper operational procedures. This documentation can serve as a quick reference guide, assisting staff in recalling critical tasks. By fostering a culture of proactive maintenance and education, you not only enhance the safety and efficiency of your boiler system but also empower your team to contribute to its optimal performance:

- Conduct regular training sessions focusing on safe operations.

- Encourage vigilance in monitoring boiler gauges and fuel consumption.

- Create easy-to-follow manuals or checklists for operational procedures.

Utilizing Advanced Monitoring Technologies

Utilizing advanced monitoring technologies for your boiler system is a strategic decision that can significantly enhance efficiency between annual inspections. Implementing sensors that continuously track temperature, pressure, and emissions can help you gain real-time insights into your boiler's performance. This proactive approach allows you to address any anomalies swiftly, ultimately preventing issues from escalating into costly repairs.

Installing remote monitoring systems can also provide you with alerts regarding vital performance metrics. For example, if a sensor detects a rise in pressure beyond predetermined limits, you can take immediate action to adjust operations or schedule maintenance. By maintaining oversight of your boiler system, you can ensure it operates within optimal parameters, effectively safeguarding both personnel and equipment while minimizing downtime.

Furthermore, integrating data analytics tools can help you assess trends over time, allowing you to make informed decisions about maintenance schedules and operational adjustments. This data-driven approach can improve the overall reliability of your boiler system, reducing the risks associated with unexpected failures. Ultimately, investing in advanced monitoring technologies reflects a commitment to quality, efficiency, and safety within your facility.

Navigating Legal Requirements and Compliance Standards

Familiarizing yourself with local and national inspection regulations is essential for maintaining compliance during your annual boiler inspection. You must ensure that your inspector holds the necessary qualifications and certifications. Accurate compliance documentation is vital to prove adherence to safety standards, helping you avoid penalties for non-compliance. Each of these aspects will be addressed in the following sections, focusing on practical steps you can take to navigate legal requirements effectively.

Understanding Local and National Inspection Regulations

Understanding local and national inspection regulations is essential for your boiler compliance. These regulations dictate the requirements for regular inspections, ensuring safety and efficiency in operation. You should familiarize yourself with the specific guidelines relevant to your location, as they can vary significantly based on jurisdiction and boiler type.

Being aware of these regulations helps you avoid penalties and operational interruptions. For example, local regulations may require specific certifications for inspectors, while national standards, such as those set by the American Society of Mechanical Engineers (ASME), provide uniform guidelines for safe operations. Keeping track of these requirements empowers you to ensure all inspections adhere to the necessary legal codes.

Proactively meeting regulatory demands not only safeguards your facility but also enhances your boiler system's performance. Investing time in understanding these regulations allows you to establish a proactive maintenance culture, fostering accountability and safety awareness among your team. Here are key components of navigating legal requirements and compliance standards:

- Familiarize yourself with local and national inspection regulations.

- Ensure that your inspector holds the necessary qualifications.

- Maintain accurate compliance documentation to avoid penalties.

Ensuring Inspector Qualifications and Certifications

To ensure the safety and efficiency of your boiler system, verifying the qualifications and certifications of your inspector is essential. A qualified inspector typically holds industry-recognized certifications, such as those from the National Board of boiler and Pressure Vessel Inspectors or similar state-level organizations. By confirming their credentials, you gain confidence that they possess the necessary skills and knowledge to conduct thorough inspections in compliance with legal requirements.

Moreover, experienced inspectors are well-versed in the specific regulations relevant to your facility's location and boiler type. They can provide valuable insights about local and national inspection standards, enabling you to remain compliant and avoid potential fines or operational disruptions. When discussing your needs with potential inspectors, do not hesitate to ask about their past experiences and training, as this information can help you gauge their expertise.

Utilizing an inspector who understands the nuances of boiler operation and safety protocols is critical for successful inspections. Regular engagement with regulatory changes equips them to offer updated advice on best practices, ensuring your facility stays aligned with current standards. This partnership not only supports a proactive maintenance culture but also enhances the performance and longevity of your boiler system.

Maintaining Accurate Compliance Documentation

Maintaining accurate compliance documentation is fundamental for safeguarding your facility's boiler system. This documentation should include records of all inspections, repairs, and maintenance activities, as having organized files readily available can streamline the inspection process and demonstrate your commitment to safety standards. When you keep thorough records, you not only facilitate compliance but also build trust with regulatory bodies and enhance your facility’s credibility.

It’s essential to track and document every detail related to your boiler system's operation and maintenance. This includes dates of service, performed tasks, and any components replaced, which can help you identify patterns or recurring issues over time. By regularly updating these documents, you can ensure that all compliance standards are met, and you will be better prepared in case of audits or inspections, ultimately protecting your facility from potential penalties.

Moreover, accurate documentation acts as a valuable tool for your team to reference and assess the boiler’s operational history. When your staff is familiar with previous inspections and repairs, they can proactively address any emerging issues before they escalate into larger problems. Investing time in maintaining comprehensive compliance records not only enhances safety but also contributes to the efficient and reliable operation of your boiler system.

Avoiding Penalties for Non-Compliance

To avoid penalties for non-compliance, it is essential to stay informed about local and national regulations governing boiler inspections. Familiarize yourself with the specific requirements that apply to your facility and ensure that your inspection schedule aligns with these guidelines. This proactive approach will help you maintain compliance and prevent any costly fines or operational disruptions.

Regularly review your record-keeping practices to ensure that all inspection reports, maintenance activities, and compliance documents are up to date. Accurate documentation not only supports your compliance efforts but also demonstrates your commitment to safety and efficiency. By keeping thorough records, you can quickly respond to any regulatory inquiries and build trust with relevant authorities.

Engaging qualified inspectors with a proven track record will also help you navigate compliance issues effectively. When choosing an inspector, verify their credentials and experience to ensure they are knowledgeable about the specific laws and standards applicable to your boiler system. Collaborating with an expert can provide valuable guidance on best practices, further reducing your risk of non-compliance and enhancing the overall safety of your operations.

Conclusion

A comprehensive guide to annual boiler inspection procedures is essential for ensuring safety, efficiency, and regulatory compliance in your facility. Regular inspections help identify potential issues early, significantly reducing operational costs and preventing hazardous conditions. By establishing a routine maintenance schedule and training staff, you enhance the reliability and longevity of your boiler system. Prioritizing these inspections safeguards your facility, protects personnel, and fosters a proactive maintenance culture that ultimately leads to smoother operations.

Resources:

Learn about HVAC

Learn about boilers