Is your boiler struggling to maintain optimal performance? Regular maintenance is key to ensuring your heating system operates efficiently and safely. In this guide, we’ll explore essential maintenance practices, including daily tasks, seasonal tips, and troubleshooting strategies to address common boiler issues. By following these best practices, you can enhance boiler efficiency, save on energy costs, and avoid unexpected breakdowns. Don’t let poor ventilation or a clogged air filter prevent your chimney from functioning effectively. Read on to keep your boiler running smoothly and efficiently.

Understanding the Importance of Regular Boiler Maintenance

Regular boiler maintenance is essential for enhancing the efficiency and lifespan of your heating system. By paying attention to components like the heat exchanger and ensuring the proper function of sensors and steam traps, you can minimize safety risks while meeting regulatory compliance. Additionally, well-maintained boilers reduce costs and offer environmental benefits through improved efficiency, ultimately protecting your investment.

How Maintenance Enhances Boiler Efficiency and Lifespan

Regular preventative maintenance of your boiler is crucial for ensuring safety and enhancing efficiency. By scheduling routine checks, you can identify potential issues before they lead to failure. For instance, monitoring the pilot light's operation can prevent dangerous scenarios and improve overall heat transfer efficiency, allowing your system to perform better under normal conditions.

Another key aspect of maintenance involves inspecting components like the heat exchanger. Built-up scale or corrosion can significantly hinder heat transfer, resulting in wasted energy and higher utility costs. By addressing these issues through regular maintenance, you can prolong the lifespan of your boiler while ensuring optimal performance and safety.

Additionally, proper maintenance fosters peace of mind by reducing the risk of unexpected breakdowns. A thorough examination of sensors and other vital parts encourages reliability, which is essential during peak heating seasons. Understanding the effect of regular maintenance on your boiler can help you safeguard your investment and maintain a comfortable environment in your home or business.

Safety Risks Associated With Neglected Boilers

Neglecting boiler maintenance poses significant safety risks, particularly concerning the pressure vessel integrity. Over time, accumulated corrosion and scale can compromise the structure, possibly leading to catastrophic failures. This can create hazardous situations where hot steam or water escapes, putting lives at risk and damaging property.

Another critical factor is the flame quality. An improperly maintained boiler can experience fluctuations in flame stability, which may result in unsafe operating conditions. Regular checks of the flame and sensors help ensure that combustion occurs efficiently, reducing the risk of carbon monoxide leaks, which can be deadly.

Moreover, water quality plays a vital role in boiler safety. Poor water quality can lead to various issues, including scale build-up and corrosion. To mitigate these hazards, you should regularly inspect components like the sight glass, which allows you to monitor water levels and clarity. Maintaining proper water quality standards is essential to prevent costly repairs and ensure safe operation:

- Regularly inspect the pressure vessel for signs of wear or damage.

- Monitor the flame quality and adjust burner settings as necessary.

- Check water quality and ensure appropriate treatment is used to prevent scaling.

- Utilize the sight glass for real-time monitoring of water levels.

Meeting Regulatory Compliance and Industry Standards

Meeting regulatory compliance is crucial for any boiler system. Adhering to local laws and requirements helps avoid penalties and ensures that your boiler operates within safe limits. Regular maintenance allows you to inspect vital components like the pressure relief valve and ensures that these safety measures function properly, ultimately reducing the risk of costly downtime and enhancing operational safety.

Your expert commitment to maintenance can significantly impact your boiler's performance and reliability. For example, by scheduling routine checks, you can confirm that your furnace meets industry standards, thereby safeguarding your investment. This proactive approach reduces the likelihood of unexpected failures and keeps your heating system running efficiently while fulfilling compliance obligations.

Incorporating a regular maintenance schedule not only aids in meeting regulatory compliance but also encourages a culture of safety and efficiency in your operation. This practice ensures that all components, including controls and sensors, are functioning correctly, minimizing operational risks. Keeping your boiler in top condition helps you maintain a comfortable environment while adhering to regulatory standards, ultimately supporting your overall business objectives.

Achieving Cost Savings Through Proper Maintenance

Achieving cost savings through proper boiler maintenance is essential for maximizing efficiency and extending the lifespan of your system. Regular checks of critical components can prevent issues like corrosion, which can lead to costly repairs and reduced performance. By maintaining the integrity of steel components and ensuring optimal combustion conditions, you can significantly lower your operational expenses while enhancing safety.

Utilizing a comprehensive maintenance checklist allows you to address potential problems before they escalate systematically. For instance, monitoring the system for potential carbon monoxide leaks during routine inspections not only protects your investment but also safeguards your home or business. By taking proactive steps, you reduce the risk of unexpected breakdowns and the associated costs of emergency repairs.

Furthermore, maintaining high water quality helps prevent scale formation and keeps the system operating efficiently. With regular maintenance, you ensure that all parts work harmoniously, reducing energy consumption and enhancing overall performance. This not only leads to immediate savings but also supports long-term financial planning by mitigating the risk of significant repairs down the line:

- Regular inspection of steel components to prevent corrosion.

- A maintenance checklist should be used to address potential issues proactively.

- Monitoring for carbon monoxide leaks to enhance safety and compliance.

- Maintaining water quality to improve boiler efficiency.

Environmental Benefits of Maintaining an Efficient Boiler

Maintaining an efficient boiler plays a significant role in reducing carbon emissions, which contributes to a healthier environment. When a boiler operates effectively, it burns fuel more completely, leading to fewer harmful emissions released into the atmosphere. Regular maintenance ensures that components are functioning optimally, which minimizes the chances of incomplete combustion and reduces carbon output, making your establishment more eco-friendly.

Another environmental benefit of diligent boiler maintenance is the reduction of condensation problems. When a boiler does not function efficiently, moisture can accumulate, leading to wear and tear on pipes and other components. This not only affects the boiler's efficiency but can also lead to leaks that waste water and energy. By ensuring your boiler feedwater system is regularly checked and maintained, you can prevent moisture-related issues, thus conserving valuable resources.

Furthermore, properly maintained boilers tend to use energy more efficiently, which translates into lower fuel consumption. This efficiency not only saves you money but also decreases the environmental impact of your heating system. Regular inspections allow you to monitor wear on critical components and promptly address any issues, ensuring that your boiler continues to operate at peak efficiency and contributes to a sustainable future.

Daily Boiler Maintenance Tasks for Optimal Performance

Monitoring and recording operating parameters is crucial for maintaining optimal boiler performance. You should inspect for leaks, corrosion, and damage to safeguard the integrity of the system. Checking water levels and treatment systems ensures proper operation, while adequate fuel supply and combustion quality impact efficiency. Finally, clearing combustion air vents and openings promotes safe and effective fuel use, whether you're utilizing oil or a heat pump system.

Monitoring and Recording Operating Parameters

Monitoring and recording operating parameters are fundamental to ensuring your boiler runs efficiently. Keeping an eye on pressure levels helps you quickly identify any irregularities that may signal a malfunction or potential system failure. For example, if you notice a significant drop in pressure, it could lead to improper operation, affecting overall heating performance.

Additionally, regularly checking the water treatment process is vital in maintaining optimal boiler function. Ensuring the water quality meets required standards prevents issues such as scaling and corrosion, which can damage components and decrease efficiency. It's also crucial to monitor the flue system for blockages or leaks, as these factors can impact combustion quality and overall boiler safety.

By establishing a routine for troubleshooting common issues, you can address problems proactively before they escalate. Regularly reviewing tank levels and monitoring operating parameters allows you to catch discrepancies early. Implementing these best practices not only enhances performance but also contributes to the longevity of your boiler system, ultimately saving you time and money:

- Monitor pressure levels regularly to detect irregularities.

- Check water treatment processes to maintain water quality.

- Inspect the flue system for blockages or leaks.

- Establish a troubleshooting routine for common issues.

- Review tank levels to catch discrepancies early.

Inspecting for Leaks, Corrosion, and Damage

Inspecting for leaks, corrosion, and damage is a critical component of daily boiler maintenance that ensures your system operates at peak efficiency. Regularly checking for leaks in your boiler system can prevent the waste of valuable boiler water and reduce the risk of more severe problems down the line. Addressing leaks promptly not only safeguards your investment but also enhances the overall performance of your heating system.

Corrosion is another concern that requires your attention during inspections. It can develop over time, especially in areas where moisture accumulates or in components that are exposed to high levels of soot and debris. By identifying signs of corrosion early, you can take necessary actions, such as replacing affected parts or implementing preventive measures, which will help maintain the longevity of your boiler and improve fuel efficiency.

Lastly, pay close attention to any visible signs of damage to boiler components. Regular inspections will allow you to catch issues before they escalate into larger, costlier repairs. Look for unusual wear or physical damage that may affect operational safety, particularly in systems using natural gas, where a malfunction can pose serious risks. Address these factors to ensure your boiler remains reliable and efficient:

- Inspect for leaks around connections and fittings.

- Check for corrosion on metal surfaces and components.

- Look for soot buildup that could affect combustion quality.

- Evaluate the condition of seals and gaskets for wear.

- Examine all pipes for damage or degradation.

Checking Water Levels and Treatment Systems

Checking water levels and treatment systems is a critical daily task that ensures your boiler operates efficiently. Maintaining the correct water level is essential to prevent damage from overheating, which can occur due to insufficient water. Frequent inspections of water levels also allow you to identify any leaks or issues early, saving you from costly wear and tear on your equipment and potential warranty claims.

Water quality plays a vital role in the longevity of your boiler. Regularly testing the water for debris and maintaining proper treatment can prevent scaling and corrosion, which can compromise the integrity of the system. If left unchecked, these issues may lead to significant efficiency losses and more frequent breakdowns requiring repairs, negatively impacting your overall HVAC performance.

Moreover, you should keep an eye on the treatment systems to ensure they are functioning correctly. This includes monitoring chemicals to prevent deposits and adjusting levels as needed. By being proactive with your boiler inspections and maintaining optimal water levels, you enhance the reliability and efficiency of your heating system, thereby extending its lifespan and ensuring your comfort consistently.

Ensuring Adequate Fuel Supply and Combustion Quality

To ensure optimal boiler performance, it's vital to verify that there's an adequate fuel supply at all times. A consistent fuel source allows your boiler to operate efficiently, preventing unexpected downtimes or system failures. If you encounter any issues with fuel delivery or note irregularities in boiler operation, such as fluctuations in performance, it could indicate a leak or blockage that needs immediate attention.

Combustion quality is equally critical and influences overall system efficiency. Regular checks of the combustion process help you identify problems such as improper air-to-fuel ratios or burner malfunctions. By monitoring these parameters, you can adjust your settings promptly to maintain high combustion efficiency, which not only enhances performance but also reduces potential emissions.

Additionally, don’t overlook the role of supportive components like pumps in ensuring a steady fuel supply to your boiler. These systems need routine maintenance as well, as any failure in the pump can lead to inadequate fuel delivery. Keeping everything in check will help you maintain high operating standards and extend the life of your boiler, ensuring a safe and effective heating solution in your home or business.

Clearing Combustion Air Vents and Openings

Clearing combustion air vents and openings is a crucial daily maintenance task for ensuring optimal boiler performance. These vents allow for proper airflow, which is essential for efficient water heating and safe operation. By keeping these areas unobstructed, you prevent blockages that could hinder the combustion process, allowing for the effective expulsion of flue gas.

Regularly inspecting and cleaning combustion air vents guarantee that your boiler operates at peak efficiency. This practice not only helps maximize the performance of your HVAC Parts but also promotes safety by reducing the risk of dangerous emissions. Failure to maintain these vents can lead to overheating, triggering the safety valve and resulting in costly repairs or system failures.

Furthermore, monitoring the condition of your combustion air openings can significantly extend the lifespan of your HVAC Supplies. Dust, debris, and other obstructions can accumulate over time, hampering airflow and affecting overall system efficiency. By committing to this daily task, you contribute to a safer environment while enhancing your boiler’s effectiveness.

- Inspect combustion air vents regularly for blockages.

- Clean openings to ensure optimal airflow and efficiency.

- Monitor air supply to prevent overheating and protect the safety valve.

- Check for signs of wear or damage around the vents.

- Maintain a record of inspections to track any recurring issues.

Weekly and Monthly Boiler Maintenance Routines

To ensure optimal boiler performance, you should incorporate weekly and monthly maintenance routines. This includes testing safety valves and control functionality, thoroughly examining burners and fuel delivery components, and verifying the operation of low water cutoffs. Regular cleaning of heat transfer surfaces and flue passages aids in efficiency while analyzing maintenance logs reveals important performance trends that can indicate the effectiveness of your Radiant Heating and Cooling system.

Testing Safety Valves and Control Functionality

Testing safety valves and control functionality on a weekly or monthly basis is essential to keep your boiler operating safely and efficiently. These components play a crucial role in regulating pressure within the system, which is vital to prevent dangerous overpressure situations. By routinely inspecting and testing these valves, you can avoid potential malfunctions and ensure they're functioning as intended.

During your testing process, look for any signs of wear or corrosion that could impair the valve's performance. A valve that doesn't open or close properly can lead to significant safety hazards, including boiler explosions in extreme cases. By proactively examining these valves and controls, you ensure that your system remains compliant with safety regulations while enhancing the overall reliability of your heating system.

In addition to safety considerations, testing controls regularly helps maintain optimal boiler performance. You want to make sure all control systems communicate effectively, allowing the boiler to operate at peak efficiency. If issues arise with sensors or electronic controls, address them promptly to prevent system inefficiencies or breakdowns, leading to costly repairs and downtime.

Examining Burners and Fuel Delivery Components

Examining burners and fuel delivery components is vital for maintaining boiler efficiency and safety. You should regularly inspect burners for proper operation, checking for any signs of wear or buildup that could affect combustion quality. A properly functioning burner ensures optimal fuel-to-air ratios, which directly influences your boiler's performance and the quality of heat produced.

In addition to checking burners, it's crucial to evaluate the entire fuel delivery system. Assessing fuel lines and valves for leaks or blockages will help prevent outages and ensure your boiler operates smoothly. Any irregularities may lead to efficiency losses or unexpected shutdowns, which could disrupt your heating service and increase operational costs.

Regular maintenance of these components not only boosts reliability but can also enhance safety. If burners are not functioning correctly, they could lead to dangerous situations, including emissions of harmful gases. By taking the time to examine burners and fuel delivery systems, you protect your investment and ensure a safe, effective heating solution for your property.

Verifying Operation of Low Water Cutoffs

Verifying the operation of low water cutoffs is essential for maintaining optimal boiler performance and safety. These devices play a critical role in preventing boiler damage by shutting down the system if water levels drop too low. Regularly testing these cutoffs helps you ensure they function properly and can eliminate any risk of overheating or system failures due to low water levels.

To verify operation, conduct straightforward inspections of each low water cutoff device routinely. Check for any signs of wear, sediment buildup, or blockages that could obstruct their functionality. Addressing these potential issues early can prevent costly repairs and extend the lifespan of your boiler system, ultimately safeguarding your investment.

Additionally, during low water cutoff tests, simulate low water conditions by manually lowering the water level to confirm that the device triggers appropriately. This proactive approach enables you to detect any malfunctions before they lead to serious complications. By incorporating regular verification of low water cutoffs into your maintenance routine, you can enhance the reliability and performance of your heating system, ensuring it operates safely and efficiently.

Cleaning Heat Transfer Surfaces and Flue Passages

Cleaning the heat transfer surfaces and flue passages of your boiler is a fundamental task in maintaining optimal performance. Over time, soot and debris can accumulate, hindering the efficiency of heat transfer. By scheduling regular cleanings, you ensure that your boiler operates at peak efficiency, reducing unnecessary energy consumption and costs.

Regularly inspecting these areas allows you to identify and eliminate blockages that could impair combustion quality. A clear pathway for flue gases not only enhances the overall operation of your boiler but also minimizes the risk of dangerous emissions. Focusing on the cleanliness of these components directly contributes to a safer and more efficient heating environment.

Incorporating this cleaning routine into your weekly or monthly maintenance schedule can lead to significant long-term benefits. You empower yourself to extend the lifespan of your boiler, prevent costly breakdowns, and maintain a consistently comfortable atmosphere in your space. By staying proactive with these cleaning practices, you protect your investment and ensure reliable heating when you need it most.

Analyzing Maintenance Logs for Performance Trends

Analyzing maintenance logs is crucial for understanding your boiler's performance trends and identifying potential issues before they escalate. By regularly reviewing records of past maintenance activities, you can spot patterns, such as recurring problems or deviations from normal operating conditions. This proactive analysis helps you take corrective actions in a timely manner, ensuring your system operates at peak efficiency and remains safe.

When you monitor key performance indicators, like pressure levels and temperature readings, you’ll gain insights into your boiler's operational health. If you notice unusual fluctuations or consistent drops in efficiency, you may need to investigate specific components further. For example, a decline in performance could indicate a buildup of scale in the heat exchanger or an issue with the fuel delivery system, guiding your maintenance efforts effectively.

Furthermore, correlating maintenance activities with operational changes can improve your long-term planning. Tracking repairs alongside energy consumption metrics allows you to evaluate the cost-effectiveness of your maintenance strategies. As you develop a deeper understanding of your boiler's needs, you'll be better positioned to make informed decisions that support reliability, compliance, and overall heating efficiency in your home or business.

Seasonal Boiler Maintenance Tips and Best Practices

Preparing your boiler for seasonal changes is critical for maintaining optimal performance. This includes gearing up for increased demand during winter, conducting proper off-season shutdown procedures, and preventing freeze damage in colder months. You’ll also learn about implementing thermal shock prevention techniques and adjusting water treatment for seasonal variations, ensuring your heating system runs smoothly and efficiently all year long.

Preparing for Increased Demand During Winter

As winter approaches, preparing your boiler for increased demand becomes essential for optimal performance. You should conduct a thorough inspection of all components, focusing on critical areas such as the heat exchanger and burners to ensure they are clean and functioning properly. Addressing any buildup or corrosion early can prevent potential breakdowns in the peak heating season, saving you from costly repairs and discomfort.

Ensure your boiler is equipped to handle the higher energy requirements of colder temperatures by checking water levels and treatment systems. Maintaining proper water quality is crucial as it prevents scale buildup and corrosion, which can compromise the efficiency of your heating system. Additionally, monitor your fuel supply to ensure consistency, as disruptions can lead to significant operating issues during winter when demand is at its highest.

Finally, consider implementing a proactive maintenance schedule tailored to winter conditions. Regularly test safety features, including pressure relief valves, to confirm they function correctly under increased load. This not only enhances the safety and efficiency of your boiler but also gives you peace of mind as you rely on your heating system to keep your environment comfortable during the frigid months ahead.

Conducting Off-Season Shutdown Procedures

Conducting off-season shutdown procedures for your boiler is crucial to ensure it remains in optimal condition during periods of inactivity. Start by thoroughly cleaning the boiler and removing any debris or soot that may have accumulated. This will help prevent corrosion and other issues that could develop while the system is not in use.

Next, make sure to drain the boiler and associated piping completely to prevent water from freezing, which can lead to serious damage. Additionally, applying a protective coating to vulnerable parts can help fend off corrosion and maintain the integrity of your boiler as it sits idle. This proactive step protects your investment, ensuring a smooth startup when you're ready to heat your space again.

Finally, consider checking and adjusting your water treatment methods before shutting down the boiler. Properly treating the water can prevent scale buildup and ensure internal components are safeguarded. By following these shutdown procedures, you’ll significantly reduce the likelihood of encountering issues when you bring your boiler back into service, maintaining its efficiency and reliability.

Preventing Freeze Damage in Colder Months

Preventing freeze damage in colder months is critical to maintaining optimal boiler performance. One of the first actions you should take is to insulate any exposed pipes and components to shield them from the harsh winter temperatures. Materials like foam insulation or heat tape can effectively prevent freezing, ensuring your boiler operates without interruption.

Another practical step is to regularly check for leaks or areas of condensation around your boiler. Any moisture can lead to ice formation, which presents a serious risk to pipe integrity and overall system performance. By conducting routine inspections, you can catch issues early and take necessary steps to alleviate potential freeze damage before the cold weather sets in.

Finally, consider adjusting your boiler settings to maintain a minimum water temperature during the winter months. This practice helps alleviate the risk of freezing while enhancing the efficiency of your heating system. To summarize, here are essential steps for preventing freeze damage:

- Insulate exposed pipes and components with foam or heat tape.

- Regularly inspect for leaks and condensation to catch problems early.

- Adjust boiler settings to maintain minimum water temperatures during winter.

Implementing Thermal Shock Prevention Techniques

Implementing thermal shock prevention techniques is vital for maintaining the integrity of your boiler system. Sudden changes in water temperature can lead to stress fractures in components, especially in cast iron boilers. By gradually adjusting the temperature when starting your system, you can help mitigate these risks and extend the lifespan of your equipment.

One effective method is to use a temperature control system that monitors and adjusts heating rates. This allows you to ramp up temperatures slowly, preventing the stresses that can occur with rapid heating. Additionally, maintaining consistent water temperature levels can aid in reducing thermal shock and enhancing overall boiler performance.

Regularly inspecting your boiler for stress points and signs of thermal fatigue is also crucial. Keep an eye on joints and seals that may be affected by temperature fluctuations. By addressing any potential issues early, you can maintain the efficiency and longevity of your heating system while ensuring safety and compliance with industry standards:

- Gradually adjust water temperature during startup to prevent stress fractures.

- Utilize a temperature control system for effective heating rate management.

- Monitor joints and seals for signs of thermal fatigue regularly.

Adjusting Water Treatment for Seasonal Changes

Adjusting water treatment for seasonal changes is essential for maintaining optimal boiler performance. As temperatures drop, water chemistry can change, potentially leading to issues such as scaling or corrosion. You must regularly check and adjust water treatment chemicals to ensure your boiler water remains within safe and effective parameters, particularly during cold months when the system experiences increased demand.

During winter, factors like cold water supply and increased heating needs can impact your boiler's efficiency. This is the time to focus on preventing scale buildup by optimizing water hardness levels. You may want to consider adding or adjusting chemicals that soften water or inhibit scale formation, as a well-balanced treatment helps reduce maintenance costs and prolong the life of your boiler system.

Moreover, it’s crucial to perform regular tests to monitor pH levels and the overall water quality. An imbalance can lead to problems such as corrosion and decreased efficiency, making it vital to tackle these issues proactively. Regularly updating your water treatment method based on seasonal changes helps maintain comfort in your home or business and ensures that your heating system operates at peak performance:

- Regularly check and adjust water treatment chemicals to combat scaling and corrosion.

- Optimize water hardness levels to prevent costly maintenance issues.

- Test pH levels and overall water quality to ensure safe operation.

Troubleshooting Common boiler Issues Through Maintenance

Troubleshooting common boiler issues is essential for maintaining optimal performance and efficiency. You'll learn how to resolve low-pressure and insufficient heat problems, address unusual noises and vibrations, and improve combustion efficiency to reduce fuel usage. You'll also discover how to correct temperature fluctuations and distribution issues, as well as the necessary steps to take when the boiler fails to start.

Resolving Low Pressure and Insufficient Heat Problems

When you experience low pressure and insufficient heat from your boiler, the first step is to inspect the pressure gauge. If it indicates levels below the manufacturer's recommended settings, check for any visible leaks in the system or radiator valves. Addressing leaks promptly can prevent further drops in pressure and enhance the overall heating efficiency of your system.

Another potential cause of low pressure is air trapped in the heating system. Bleeding the radiators helps release trapped air, allowing the hot water to circulate properly and restore heat. Ensure that your boiler is turned off before bleeding the radiators and use a cloth to catch any water that may escape during the process, ensuring there’s no additional water loss that could affect pressure.

Lastly, assess the boiler’s water supply. Insufficient water levels can lead to improper pressure, resulting in inadequate heating. Regularly checking the water level in the system and refilling it as necessary can help maintain optimal pressure. By staying proactive with these checks, you’ll enhance your boiler’s performance and ensure a comfortable environment in your home or business.

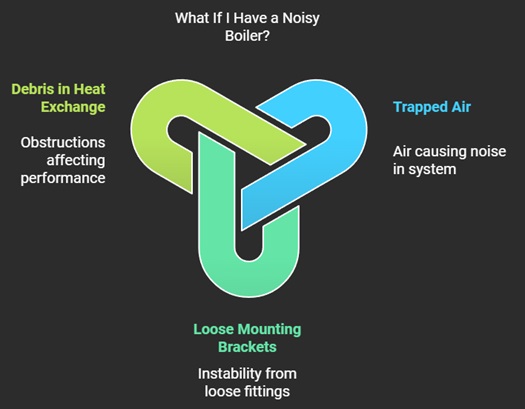

Addressing Unusual Noises and Vibrations

Addressing unusual noises and vibrations from your boiler is vital for maintaining optimal boiler performance. If you hear banging, gurgling, or whining sounds, these may indicate underlying issues such as trapped air, sediment buildup, or component wear. Identifying these noises early can prevent more significant problems and costly repairs in the future.

Start by checking for air trapped in the system, as this can cause banging sounds during operation. To resolve this, you should bleed the radiators, releasing the trapped air and restoring proper water flow. If vibrations are excessive, inspect the mounting brackets and securing components; loose fittings may cause instability, increasing wear on the system.

Another common cause of unusual noises is debris or calcification within the heat exchange surfaces. Regularly cleaning these areas can improve performance and reduce disruptive sounds. Keeping a consistent maintenance schedule helps ensure any anomalies are addressed promptly and contributes to the longevity of your heating system. Take action today to identify and troubleshoot your boiler's unusual noises and vibrations:

- Inspect for trapped air and bleed the radiators as necessary.

- Check mounting brackets for looseness and secure them tightly.

- Clean heat exchange surfaces to minimize debris and calcification.

Improving Combustion Efficiency to Reduce Fuel Usage

Improving combustion efficiency in your boiler is vital for reducing fuel usage and enhancing overall system performance. Begin by checking the air-to-fuel ratio, as this balance directly influences combustion. An incorrect ratio can lead to incomplete combustion, wasting fuel and increasing emissions, which is not only costly but also harmful to the environment.

Regularly inspecting and cleaning the burner is another essential step. Clogged burners can lead to uneven heating and increased fuel consumption. By keeping the burner free from soot and other debris, you ensure a consistent and efficient combustion process, allowing your boiler to operate at its best.

You should also monitor your boiler’s flame quality. A stable, blue flame indicates efficient combustion, while a yellow or flickering flame can signal potential issues that need addressing. Noticing these changes early enables you to make timely adjustments, ultimately saving you money on fuel costs and improving the reliability of your heating system:

- Check the air-to-fuel ratio regularly to ensure proper combustion.

- Clean burners to prevent soot buildup and enhance efficiency.

- Monitor flame quality for signs of combustion issues.

Correcting Temperature Fluctuations and Distribution Issues

Temperature fluctuations in your boiler can signal underlying issues that require immediate attention. If you notice that certain areas of your space are excessively hot or cold, it may indicate problems with the thermostat or misalignment in your heating system. Regularly checking and calibrating the thermostat can ensure accurate temperature control, helping maintain a consistent indoor environment.

Additionally, improper distribution of heat can stem from air trapped in the system or blockages in the piping. To address this, you should regularly bleed your radiators to remove trapped air, allowing hot water to circulate effectively. This simple maintenance task can significantly enhance heating efficiency and contribute to ensuring that every room maintains an even temperature.

If you continue to experience temperature inconsistencies after these basic adjustments, it may be worth evaluating your boiler’s water circulation system. Poor circulation can stem from issues such as pump failure or sediment build-up in the pipes. Addressing these problems swiftly will help restore optimal boiler performance and ensure reliable heating throughout your home or business.

Steps to Take When the Boiler Fails to Start

If your boiler fails to start, the first step is to check the power supply. Verify that the unit is plugged in and that the circuit breaker hasn't tripped. This simple check can resolve many starting issues, preventing unnecessary service calls.

Next, inspect the thermostat settings. Ensure that the thermostat is set to a temperature higher than the current room temperature, as this triggers the boiler to initiate. If the thermostat is malfunctioning, you might need to replace it to regain control over your heating system.

Lastly, examine the fuel supply. For gas boilers, check that the gas valve is open, and for oil boilers, ensure there’s enough fuel in the tank. Should you identify any issues in these areas, address them promptly to restore your boiler’s functionality and maintain optimal performance:

- Check the power supply and circuit breaker.

- Inspect and adjust the thermostat settings.

- Examine the fuel supply and valve status.

Implementing a Preventative Boiler Maintenance Plan

To achieve optimal boiler performance, it’s crucial to implement a preventative maintenance plan. This plan should include creating a customized maintenance schedule tailored to your system's needs, training personnel on effective maintenance procedures, and utilizing advanced boiler monitoring technology for real-time insights. Collaboration with professional service providers further enhances your maintenance efforts while documenting all activities ensures accountability and tracking of performance over time.

Creating a Customized Maintenance Schedule

Creating a customized maintenance schedule for your boiler is vital for ensuring optimal performance and longevity. Start by assessing your specific boiler type and usage patterns, as different systems may require varying maintenance frequencies. For instance, commercial boilers might need more frequent checks due to higher usage, while residential units could follow a quarterly or biannual schedule, allowing you to tailor maintenance tasks effectively.

Include specific tasks such as pressure checks, leak inspections, and cleaning procedures in your maintenance plan. This approach not only helps you keep track of essential tasks but also equips you with a clear timeline of what needs attention and when. By documenting these tasks in a log, you can identify recurring issues and adjust your maintenance strategies accordingly, enhancing your boiler's efficiency and safety.

Moreover, consider scheduling professional inspections at least once a year as part of your custom plan. Partnering with experienced HVAC professionals for these checks can provide you with insights and solutions that go beyond basic maintenance. This proactive step ensures that your boiler operates smoothly and reduces the likelihood of unexpected breakdowns, ensuring a comfortable environment throughout the year.

Training Personnel on Maintenance Procedures

Training personnel on maintenance procedures is a foundational element for achieving optimal boiler performance. You need to ensure that your staff understands how to conduct regular inspections and identify potential issues that could compromise efficiency and safety. Providing hands-on training and access to comprehensive manuals will empower your team to recognize and resolve problems before they escalate, safeguarding your investment in the heating system.

Engaging your staff in the training process creates a culture of accountability and diligence within your organization. Encourage them to participate in team discussions and share insights from their direct experiences with the boiler system. This collaborative approach not only enhances their understanding but also fosters teamwork, where everyone is aligned toward maintaining a high standard of operation.

Regular refresher courses and updates on new technologies related to boiler maintenance can further equip your team with essential skills. As the industry evolves, staying informed about best practices, safety regulations, and modern equipment ensures that your personnel can respond to challenges effectively. This commitment to continuous learning ultimately leads to increased reliability and efficiency in your boiler operations, enhancing the overall performance of your system.

Utilizing Advanced Boiler Monitoring Technology

Utilizing advanced boiler monitoring technology is essential for maintaining optimal performance and efficiency in your heating system. This technology allows for real-time tracking of key performance metrics, enabling you to identify potential issues before they escalate into costly repairs. By integrating sensors that monitor pressure, temperature, and fuel consumption, you gain invaluable insights into your boiler's operational health.

Implementing these monitoring systems can lead to more informed decision-making regarding maintenance schedules. For instance, if you notice a consistent drop in temperature or irregular pressure readings, you can promptly investigate and address the root cause. This proactive approach not only enhances system reliability but also prolongs the lifespan of your equipment, giving you peace of mind.

Another advantage of advanced monitoring technology is the ability to generate detailed maintenance reports. These reports can help you track performance trends over time, making it easier to justify scheduled maintenance or upgrades to stakeholders. With data-driven insights at your fingertips, you will be well-equipped to optimize your boiler's performance and ensure operational efficiency:

- Real-time tracking of performance metrics.

- Proactive decision-making regarding maintenance schedules.

- Data-driven insights for optimizing boiler performance.

Collaborating With Professional Service Providers

Collaborating with professional service providers can significantly enhance the effectiveness of your preventative boiler maintenance plan. These experts bring specialized knowledge and experience, allowing them to identify issues that may not be apparent to the untrained eye. Their insights can help you implement more efficient maintenance protocols, reducing the risk of unexpected failures and costly repairs.

When working with a professional service provider, it is essential to establish clear communication and expectations. Share your specific concerns and maintenance goals while seeking their recommendations on best practices tailored to your boiler system. This collaboration can foster a thorough understanding of your heating needs and ensure your boiler operates safely and efficiently.

Lastly, utilizing the services of a professional can streamline necessary inspections and repairs, allowing you to focus on other important aspects of your operation. Regular interactions and scheduled services with these providers create a solid foundation for ongoing support, ensuring that your boiler continues to perform at optimal levels. Here are some key aspects to consider when collaborating with professionals:

- Assess the expertise and certifications of the service provider.

- Establish clear communication regarding maintenance goals.

- Implement scheduled inspections and repairs for greater reliability.

- Seek tailored recommendations to enhance boiler performance.

Documenting Maintenance Activities for Accountability

Documenting maintenance activities is vital for maintaining accountability within your boiler maintenance plan. By keeping accurate records of inspections, repairs, and any adjustments made, you create a comprehensive history of your boiler's performance. This documentation not only aids in tracking compliance with industry standards but also helps you identify recurring issues that may need more in-depth analysis.

When you establish a systematic approach to documentation, you empower your team to maintain high standards of operation. For instance, detailing the time and type of maintenance performed can highlight trends in boiler performance, leading to proactive decision-making. Access to these historical maintenance records can streamline communication with service providers and ensure everyone is informed about the boiler's condition.

Incorporating a structured documentation process into your preventative maintenance plan ensures accountability and supports long-term efficiency. Regularly reviewing maintenance logs allows you to assess the effectiveness of your strategies and make necessary adjustments. You can enhance the boiler's reliability while optimizing its performance by leveraging these insights:

- Establish a clear format for recording maintenance tasks.

- Monitor the frequency and type of issues addressed over time.

- Utilize documented data to inform future maintenance decisions.

Conclusion

Regular boiler maintenance is crucial for ensuring optimal performance, safety, and efficiency. Implementing best practices, such as routine inspections and proper water treatment, can significantly extend your boiler's lifespan while minimizing operational costs. Proactive strategies, including monitoring performance metrics and collaborating with professionals, help you address potential issues before they escalate. By prioritizing maintenance, you protect your investment and ensure a reliable heating system, fostering a comfortable environment year-round.

Resources:

Learn about HVAC

Learn about boilers