Are you considering an oil-fueled boiler for your heating needs? With rising energy costs, many homeowners are turning to this efficient solution. In this comprehensive guide, you’ll explore the various types of oil boilers, their advantages, and essential installation and maintenance guidelines. Additionally, we’ll compare oil boilers with other heating systems and discuss environmental considerations. By understanding the workings of oil-fueled boilers, you can enhance your energy conservation efforts and make informed choices for your home’s heating system. Please read for more info, and remember to save on HVAC at PlumbersStock.

Introduction to Oil-Fired Boilers

Oil boilers are essential systems for providing heat in various settings. They consist of key components such as burners, heat exchangers, and thermostats, all of which work together to efficiently generate warmth. This guide will explore how these systems operate and highlight features like heat recovery, ventilation, and condensation, giving you a comprehensive understanding of their functionality and advantages compared to natural gas systems.

What Are Oil-Fired Boilers?

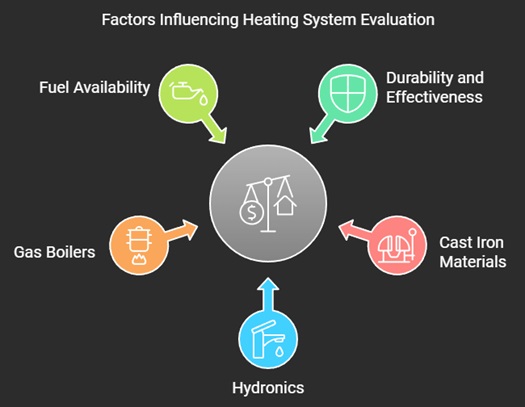

Oil-fired boilers are heating systems that utilize oil as a fuel source to generate warmth in residential and commercial spaces. These boilers are known for their durability and effectiveness in providing consistent heat, often preferred in areas where natural gas is not readily available. By incorporating advanced sensors and controls, oil-fired boilers can optimize fuel consumption and maintain comfortable temperatures effectively.

One of the defining features of oil-fired boilers is their construction, which frequently involves durable materials like cast iron. This robust design contributes to longevity and efficient heat retention, making these systems a reliable choice for many. Additionally, oil-fueled boilers often employ hydronics, a system that uses water to transfer heat, resulting in evenly distributed warmth throughout the space.

These boilers can be an excellent alternative to gas boilers, particularly in regions lacking natural gas infrastructure. By assessing your specific heating needs and the availability of fuels, you can determine whether an oil-fired boiler meets your requirements. In considering efficiency, installation, and potential fuel costs, you position yourself to make an informed decision that enhances your heating setup:

- Durability and effectiveness

- Use of cast iron materials

- Hydronics for heat distribution

- Comparison with gas boilers

- Assessment of fuel availability

Key Components of an Oil-Fired Boiler System

The key components of an oil-fired boiler system play a significant role in ensuring efficient heating performance. At the heart of these systems is the burner, which is responsible for converting the oil fuel into a flame that heats the water. This construction is critical, as the efficiency of the burner directly impacts oil heating effectiveness. Regular maintenance of the burner is essential to optimize fuel consumption and minimize emissions associated with air pollution.

Another vital element is the heat exchanger, which transfers heat generated from the combustion of fuel gas to the water circulating in your heating system. This component often utilizes durable materials that can withstand high temperatures while maximizing heat retention. When properly maintained, heat exchangers help ensure that the oil heating system operates efficiently and effectively, meeting the standards set forth by the United States Environmental Protection Agency.

Thermostats are equally important in an

- Burner - Converts oil into flame for heating.

- Heat Exchanger - Transfers heat to circulating water.

- Thermostat - Regulates temperature for comfort and efficiency.

How oil Fired Boilers Operate

Oil-fired boilers operate by utilizing an oil burner to convert fuel oil into a flame, which then heats the water in your heating system. This process begins with the oil being pumped from a storage tank to the burner, where it is atomized into fine droplets and ignited. The efficient combustion of this oil generates heat, which is then transferred to the water circulating in the system, providing reliable warmth throughout your space.

Additionally, the installation of an oil-fired boiler can significantly affect its performance and efficiency. Proper configuration ensures the burner is correctly calibrated and that the heat exchanger operates at optimal levels. This not only enhances the heating performance but also minimizes the risk of carbon monoxide emissions, safeguarding your home environment and ensuring the system complies with safety standards.

Moreover, many modern oil-fired boilers feature condensing technology, which allows them to capture and reuse some of the heat that would otherwise be lost. This advanced function enables the boiler to achieve higher efficiency ratings, reducing fuel consumption and operating costs. By understanding how these systems operate, you can better appreciate the benefits of choosing an oil-fired boiler for your heating needs:

- Components of an oil-fired boiler

- Operating principles of the oil burner

- Importance of correct installation

- Role of condensing technology in efficiency

- Safety considerations regarding carbon monoxide

Types of Oil Boilers

Understanding heating solutions requires understanding the different types of oil boilers is essential for selecting the right system for your needs. Conventional oil boilers offer reliable heating solutions, while condensing oil boilers improve efficiency with advanced technology. Combination (combi) oil boilers provide both heat and hot water in one compact unit, demonstrating versatility. This section covers their features, including warranties and materials like steel, giving you the insights needed to make an informed decision.

Conventional oil Boilers Explained

Conventional oil boilers are trusted heating systems that utilize combustion to produce heat efficiently. They burn oil to create hot gases that heat the water circulating in the boiler, ensuring a consistent and reliable source of warmth for your home or facility. By effectively utilizing boiler water, these systems provide high comfort levels even in colder climates where additional heating options may be limited.

When you consider a conventional oil boiler, you'll find that it often incorporates robust components such as a pump that circulates the heated boiler water throughout the building. This design enhances the overall effectiveness of the system and ensures that every room receives adequate warmth. Your choice of boiler will play a crucial role in system efficiency, and these boilers are typically regarded for their effective heat delivery capabilities compared to other heating methods.

It's also important to note that while conventional oil boilers focus on direct combustion, there is a growing trend toward condensing boilers that capture more energy from the exhaust gases. Although conventional models may lack some of the advanced features of heat pumps, they remain a strong choice for those looking for dependability and straightforward heating solutions. Understanding the advantages of conventional oil boilers can assist you in making a well-informed decision that aligns with your heating needs.

Understanding Condensing Oil Boilers

Condensing oil boilers are an advanced option for heating that offers improved efficiency by capturing and reusing heat from exhaust gases. By utilizing a combustion chamber designed to maximize heat recovery, these systems can achieve higher thermal efficiency compared to conventional oil boilers. This not only translates to lower fuel consumption but significantly reduces carbon emissions, making them a more environmentally friendly choice for heating your space.

Another key aspect of condensing oil boilers is their enhanced indoor air quality. The incorporation of advanced filtration and ventilation systems helps minimize pollutants and particulates generated during the combustion process. This means you can enjoy a comfortable and healthy living environment, as these boilers work to keep your air cleaner while providing effective heating throughout your home.

Corrosion-resistant materials are often used in the construction of condensing oil boilers, extending their lifespan and reducing maintenance costs. When you choose a condensing model, you are investing in a boiler that not only optimizes energy use but is also built to endure the rigors of long-term operation. The benefits included can make these boilers an attractive option for homeowners looking to enhance their heating systems:

- Improved thermal efficiency

- Lower carbon emissions

- Enhanced indoor air quality

- Long-lasting, corrosion-resistant materials

- Optimal heat recovery

Features of Combination (Combi) Oil Boilers

Combination (combi) oil boilers are versatile systems designed to cater to both heating and water heating needs within a single unit. These boilers efficiently utilize fuel oil to provide consistent warmth while also supplying hot water on demand. This dual functionality can significantly streamline your energy consumption and reduce the need for separate heating and water systems, creating a more efficient home environment.

One of the notable features of combi oil boilers is their integration with zone valves, which allow you to control the heating of different areas in your home independently. This means you can customize heating in each zone according to your personal comfort levels, maximizing efficiency and potentially lowering your energy bills. Additionally, a well-placed flue ensures that any combustion byproducts are safely directed outside, contributing to a safer indoor environment.

Modern combi oil boilers often come equipped with advanced controls that improve user experience and energy efficiency. For example, smart thermostats can optimize heating schedules and monitor system performance, allowing for a tailored approach to both heating and air conditioning needs. Understanding these features can empower you to make informed decisions about your heating setup and enhance the overall comfort of your living space.

Advantages of Using Oil-Fueled Boilers

Oil-fired boilers offer notable efficiency and performance benefits, largely due to their advanced manufacturing processes and heat exchanger designs that maximize thermal insulation and reduce waste. These systems provide flexibility in fuel options, making them ideal for off-grid homes where alternative energy sources may be limited. In the following sections, you'll discover how these advantages can significantly enhance your heating solutions.

Efficiency and Performance Benefits

One of the main efficiency benefits of oil-fired boilers is their ability to provide consistent and substantial heat output. These systems utilize advanced technology in their design, such as high-efficiency valves and heat exchangers, enabling them to optimize energy use and reduce waste. This means you can rely on oil-fired boilers to maintain the desired temperature in your home effectively, enhancing comfort during colder months.

When it comes to performance, oil furnaces demonstrate a strong capability for heating spaces quickly and efficiently. Many oil-fired boilers are equipped with radiant heating capabilities, utilizing radiators that distribute warmth evenly throughout your home. This ensures that you don’t experience cold spots, making your living environment more comfortable and energy-efficient.

Additionally, oil-fired boilers generally have a higher thermal efficiency than traditional systems, meaning they consume less fuel while delivering effective heating. This can lead to lower energy bills over time as you benefit from reduced fuel consumption. By choosing an oil-fueled boiler, you are opting for a reliable heating solution that addresses your comfort needs while maximizing energy savings.

Flexibility in Fuel Options

One significant advantage of oil boilers is their flexibility in fuel options. While these systems primarily use oil as their main fuel source, they can also accommodate alternative fuels, such as coal, under certain conditions. This adaptability can be particularly useful for homeowners or businesses in remote areas where access to various fuels may be limited.

By allowing the use of different fuel types, you can tailor your heating system to your specific energy needs and local availability. For example, if oil prices rise significantly, you might choose to switch to coal or another economical alternative. This flexibility not only keeps your heating costs manageable but also ensures you're never at the mercy of a single fuel market.

Understanding the options available enables you to make informed decisions about your heating system. It’s essential to consult with a professional before switching fuels to ensure compatibility with your oil-fired boiler and maintain efficiency. Your heating setup should always prioritize reliability and cost-effectiveness:

- Flexible fuel options can include coal and other alternatives.

- Adaptability helps in managing heating costs effectively.

- Consulting with professionals ensures compatibility and efficiency.

Ideal Solutions for Off-Grid Homes

If you live in an off-grid home, oil-fired boilers can provide a dependable heating solution. Their design allows for efficient heating even in remote locations where access to natural gas may be limited. Utilizing a robust storage tank for fuel oil ensures you have a consistent source of energy, allowing you to maintain comfort during colder months without the need for a direct energy line.

Additionally, oil-fired boilers are compatible with alternative fuel options, enhancing their versatility in off-grid scenarios. Should oil prices fluctuate or availability become a concern, you may have the option to switch to other fuels like coal, offering you flexibility in managing heating costs. This adaptability is crucial for off-grid homeowners who need to find economical solutions without compromising on heating reliability.

Moreover, the effective heat output of oil-fired boilers ensures that even in the absence of traditional energy sources, you will stay warm and comfortable. Many of these systems are constructed with durable materials, contributing to their long lifespan and resilience against harsh weather conditions. By selecting an oil-fueled boiler, you can create a sustainable and effective heating setup tailored to your off-grid living needs.

Installation and Maintenance Guidelines

Successful installation of your oil-fired boiler involves a series of critical steps to ensure optimal performance and longevity. You’ll learn about routine maintenance practices that keep your system running efficiently, along with essential safety and compliance guidelines to protect your home and family. Each of these elements plays a significant role in maximizing the benefits of your heating system.

Understanding these topics will help you make informed decisions and ensure your oil-fired boiler operates effectively, providing reliable warmth throughout your space.

Steps for a Successful Installation

To ensure a successful installation of your oil-fired boiler, you must start by assessing the space where the unit will be placed. Check for sufficient clearance around the boiler to allow for maintenance and operation. Additionally, verify that the floor can support the weight of the boiler and the fuel tank, as inadequate support could lead to safety hazards or damage over time.

Next, you should prepare the necessary connections for fuel supply, water lines, and venting. Properly positioning the oil tank and ensuring a secure fuel line is essential, as this directly affects the boiler's performance and efficiency. Make sure all connections comply with local building codes and safety regulations to prevent potential issues during operation.

After completing these initial steps, professional installation is crucial to guarantee that the boiler operates at peak efficiency. An experienced technician will help with testing system performance and making any necessary adjustments for optimal operation. Regular checks will further ensure your boiler operates safely, effectively, and within safety guidelines:

- Assess installation space for appropriate support.

- Prepare connections for fuel, water, and venting.

- Schedule professional installation for optimal performance.

Routine Maintenance Practices

Routine maintenance for your oil-fired boiler is essential to ensure its optimal performance and longevity. Regularly checking the oil filter is a vital step, as a clogged filter can reduce efficiency and lead to system failures. By changing the filter annually, you can help maintain a steady flow of fuel, which contributes to consistent heating and reduces the risk of costly emergency repairs.

An equally important aspect of maintenance involves inspecting the burner and heat exchanger. Cleaning the burner and ensuring the heat exchanger is free of soot and debris can significantly enhance the boiler's efficiency. Schedule a professional inspection at least once a year to assess these components and make any necessary adjustments to ensure your system operates safely and effectively.

Don't overlook the significance of monitoring the overall system pressure and temperature settings. Maintaining proper pressure ensures that the boiler functions as intended, preventing overheating or inadequate heating. Regularly checking and adjusting these settings, along with keeping an eye on any unusual noises or leaks, will help you identify potential issues before they escalate, providing you peace of mind throughout the heating season.

Ensuring Safety and Compliance

Ensuring safety and compliance with local building codes is paramount when installing an oil- boiler. Before proceeding with any installation, you should familiarize yourself with the specific regulations in your area. This not only protects your investment but also ensures that your heating system operates safely, minimizing any risks of hazards related to heating oil systems.

During the maintenance phase, proper checks and adherence to safety guidelines are crucial. You should regularly inspect all connections and components, ensuring that there are no leaks or signs of wear. If you detect any irregularities, it’s advisable to contact a qualified technician who can address these issues promptly and maintain compliance with safety standards.

Moreover, maintaining a safe environment involves equipping your home with carbon monoxide detectors, especially since oil-fired boilers can produce this harmful gas if not functioning correctly. Regular testing of these detectors provides an added layer of security, ensuring that you can quickly respond to any potential safety concerns while enjoying the reliable heating that an oil-fired boiler offers.

Comparing Oil-Fueled Boilers With Other Heating Systems

In this section, you will explore how oil-fired boilers compare to other heating systems, specifically gas boilers and heat pumps. You will evaluate the relative strengths and weaknesses, considering factors such as energy costs, efficiency, and performance. By assessing these elements, you can gain practical insights that help guide your decision-making process when selecting an oil-fired boiler for your heating needs.

oil Boilers Versus Gas Boilers

When considering heating solutions, oil boilers, and gas boilers present different benefits and drawbacks. oil boilers generally offer higher efficiency in colder climates, as they can produce a greater heat output quickly. Additionally, these systems are often favored in areas where natural gas isn't easily accessible, making them a practical choice for many homeowners.

Gas boilers tend to have lower fuel costs in many regions due to the availability and affordability of natural gas, which might make them more appealing if gas lines are nearby. However, these systems may require more frequent maintenance related to gas line integrity and combustion efficiency. In contrast, oil boilers often involve a straightforward maintenance routine focusing on fuel filters and burner efficiency.

Ultimately, your choice between an oil boiler and a gas boiler will depend on factors such as fuel availability, local energy prices, and your specific heating needs. Understanding the differences between these heating systems can help you make an informed decision that optimally fits your home or business:

- Oil boilers provide higher efficiency in colder climates.

- Gas boilers typically have lower fuel costs and easier maintenance. (Check out our HVAC part and accessories)

- Your choice should depend on fuel availability and heating needs.

Evaluating Oil-Fired Boilers and Heat Pumps

When evaluating oil-fired boilers and heat pumps, you should consider the distinct advantages each system offers for your heating needs. Oil-fired boilers are often favored in colder climates due to their capacity to produce substantial heat rapidly, which can be particularly beneficial during harsh winter months. On the other hand, heat pumps work efficiently in moderate climates and can provide both heating and cooling, making them a versatile option for year-round comfort.

One key factor to weigh is energy efficiency. Oil-fired boilers typically have a higher thermal efficiency compared to traditional heating systems, which translates to reduced fuel consumption and lower heating costs over time. In contrast, heat pumps utilize electricity to transfer heat rather than generate it, resulting in lower operational costs in areas where electricity rates are favorable. Understanding your local energy costs is crucial in determining which option aligns best with your budget.

Another important consideration is the environmental impact of each system. oil fired boilers can contribute to higher carbon emissions due to the combustion of fossil fuels; however, advancements in technology have made some models more environmentally friendly. Heat pumps, being more energy-efficient and often powered by renewable energy sources, tend to have a lower carbon footprint. Assessing your values and priorities regarding sustainability will help you make a well-rounded, informed choice for your heating system.

Assessing Costs and Energy Efficiency

When evaluating the costs associated with oil-fired boilers, you should consider both the upfront investment and ongoing operating expenses. While the initial purchase price for an oil boiler might be higher than that of other heating systems, its durability and effective performance often lead to significant long-term savings. The key is to balance the initial expenditure with expectations for energy efficiency and maintenance costs, which can vary based on usage and installation quality.

Energy efficiency is a crucial factor to assess when comparing oil-fueled boilers with other heating systems. Many modern oil boilers are designed to achieve high thermal efficiencies, translating to lower fuel consumption and reduced heating bills. When you select an oil boiler with advanced features like condensing technology, you can further enhance efficiency, ensuring that every drop of fuel is used effectively for heating your home.

Understanding your local energy market will help you gauge potential operating costs for oil-fired boilers compared to alternatives like gas boilers or heat pumps. Prices for heating oil can fluctuate, impacting your overall expenses, but oil-fired systems tend to perform reliably in colder climates, providing consistent heat when you need it most. By carefully analyzing these aspects, you can confidently select a heating solution that meets your budgetary constraints while delivering optimal performance and comfort.

Environmental Considerations and Sustainability

Oil boilers are essential for heating, yet their environmental impact and emission levels are significant considerations. You can explore ways to reduce this impact through technological innovations in oil boiler systems, which are designed to enhance efficiency and lower emissions. This section will provide practical insights on emission levels, strategies for minimizing environmental effects, and the latest advancements in oil boiler technology.

Emission Levels of oil Fired Boilers

Emission levels from oil-fueled boilers can vary significantly based on their design and technology. These systems typically produce carbon dioxide (CO2), nitrogen oxides (NOx), and sulfur oxides (SOx), among other compounds. By selecting modern, high-efficiency oil-fired boilers equipped with advanced combustion technology, you can help reduce harmful emissions, contributing to a healthier environment and enhancing indoor air quality.

Regular maintenance plays a critical role in managing emission levels in oil-fired boilers. Scheduled inspections ensure that burners and heat exchangers operate efficiently, minimizing waste and emissions. By adhering to maintenance schedules, you not only prolong the lifespan of your boiler but also ensure compliance with environmental regulations and standards set forth by authorities.

Choosing oil-fired boilers with condensing technology further enhances their efficiency and reduces emissions. These systems capture exhaust gases and recover lost heat, resulting in lower carbon footprints. When considering an oil-fired boiler, evaluate options that incorporate these features to maximize efficiency and minimize environmental impact:

- Minimizing carbon dioxide (CO2) emissions.

- Reducing nitrogen oxides (NOx) and sulfur oxides (SOx).

- Ensuring regular maintenance for optimal performance.

- Utilizing condensing technology to capture lost heat.

Reducing Environmental Impact

Reducing the environmental impact of oil-fired boilers begins with regular maintenance and proper tuning of the system. By ensuring that the burner and heat exchanger are functioning efficiently, you can minimize fuel consumption and lower emissions significantly. This proactive approach not only enhances the performance of your boiler but also contributes positively to environmental sustainability.

Replacing older oil-fueled boilers with high-efficiency models equipped with condensing technology can further decrease the carbon footprint of your heating system. These modern units capture waste heat from exhaust gases, allowing for better fuel utilization and reduced greenhouse gas emissions. By making this upgrade, you’re making a commitment to a more sustainable heating solution that aligns with eco-friendly practices.

Additionally, exploring alternative oil sources or blending fuels can also help reduce the environmental effects of oil-fired boilers. For instance, biofuels offer a renewable option that can lower carbon emissions when used in conjunction with traditional heating oils. Engaging in such practices can help you achieve a cleaner and more sustainable heating system while keeping your space warm and comfortable.

Innovations in oil boiler Technology

Recent advancements in oil boiler technology have significantly focused on improving their efficiency and reducing environmental impact. High-efficiency models now incorporate condensing technology, which captures and reuses heat that would otherwise be lost, thus minimizing fuel consumption. This innovation not only enhances the overall performance of oil boilers but also lowers operating costs for users compared to traditional models.

Another innovative development includes the integration of advanced control systems that optimize the combustion process in real-time. These systems adjust the fuel-to-air ratio based on the heating demand, ensuring that the boiler operates at peak efficiency. As a result, you experience enhanced comfort in your space while contributing to lower emissions and improved indoor air quality.

Investing in modern oil boilers equipped with these technological advancements allows you to address both your heating needs and sustainability goals. Many of these units now also utilize biofuels or other renewable options, providing a cleaner alternative that can further reduce your carbon footprint. By making informed choices regarding your heating system, you help create a more sustainable environment while enjoying reliable warmth in your home.

Conclusion

Understanding oil-fueled boilers is crucial for homeowners and professionals alike, as these systems provide reliable heating solutions, especially in areas lacking natural gas infrastructure. By exploring the various types, components, and operational mechanisms of these boilers, you can make informed decisions that optimize efficiency and performance. Regular maintenance and awareness of environmental impacts further enhance their effectiveness and sustainability. Embracing the advantages of oil-fired boilers not only ensures consistent warmth but also contributes to a more energy-efficient and environmentally friendly heating setup.

Resources:

Learn about HVAC

Learn about boilers