Is your boiler pilot light flickering, or has it gone out completely? This common issue can disrupt your home's heating system and leave you in the cold. In this blog post, you will learn about the role of the boiler pilot light, common reasons why it may malfunction, and a step-by-step guide to relighting it safely. By understanding these key points, you'll gain the confidence to troubleshoot the problem, ensuring your heat pump stays operational and your ignition system functions effectively. Don't let a simple pilot light issue hinder your comfort—let’s resolve it together.

Understanding the Role of the Boiler Pilot Light

The boiler pilot light plays a crucial role in igniting your heating system, ensuring it operates efficiently. You will learn about the different types of pilot light systems used in HVAC Parts boilers and watch for signs indicating your pilot light may not be functioning correctly. These insights will empower you to address issues related to your propane or gas furnace effectively, ensuring optimal performance and safety.

How the Pilot Light Ignites the Boiler

The pilot light serves as the ignition source for your boiler, initiating the heating cycle. When you turn on your heating system, either with natural gas or liquefied petroleum gas, the pilot light burns continuously, ready to ignite the main burner when there is a call for heat. This critical role ensures your boiler operates efficiently and maintains the proper temperature within your home, minimizing energy waste.

For the pilot light to function correctly, it requires a specific gas pressure. If the pressure is too low, the pilot may extinguish, while too high can cause dangerous conditions, including the release of carbon monoxide. Regularly checking the pressure and ensuring that the pilot light is lit will enhance the safety of your heating system and help you avoid costly repairs.

When you notice your boiler isn't heating properly, one of the first steps is to examine the pilot light. If it is out, you will need to relight it by pressing the button on the pilot assembly. Remember to follow safety precautions, as dealing with gas can pose risks if not managed correctly:

- Check the gas supply to ensure it is turned on.

- Inspect the pilot light assembly for any blockages.

- Adjust the pressure settings if necessary.

Types of Pilot Light Systems in Boilers

There are two primary types of pilot light systems used in boilers: traditional and electronic. Traditional pilot lights utilize a small flame that burns continuously, serving as a reliable ignition source for your central heating system. In contrast, electronic ignition systems only light the burner when needed, which can enhance energy efficiency and reduce fuel consumption, making them a popular choice for modern water heating solutions.

It's essential to recognize the potential hazards associated with pilot light malfunctions. A neglected pilot light can lead to issues such as carbon monoxide accumulation, which poses serious health risks, including carbon monoxide poisoning. Monitoring your pilot light's condition and understanding its type can help you take proactive measures to maintain your boiler’s safety and efficiency.

When troubleshooting pilot light issues, knowing your system's specifics can guide your approach. Follow these steps to ensure proper operation and address any problems effectively:

- Identify whether you have a traditional or electronic pilot light system.

- Regularly inspect the pilot light for signs of blockage or extinguishment.

- Perform necessary adjustments based on the pilot light type to maintain safe gas pressure.

Signs Your Pilot Light Is Not Functioning Properly

If your boiler fails to produce heat, one of the first signs to check is the pilot light. An extinguished pilot light indicates your system is unable to ignite the main burner, preventing your heat exchanger and pump from functioning effectively. This can lead to inadequate heating in your home, leaving you uncomfortable during colder months.

You should also be on the lookout for a yellow or flickering pilot light. This condition often suggests incomplete combustion, which could result in carbon monoxide production, posing serious health risks. Additionally, if you notice a strong smell of gas around the unit, it's crucial to turn off the gas supply immediately and contact a professional, as this could signal a gas leak that requires urgent attention.

Another important component to examine is the thermocouple. If the thermocouple is malfunctioning, it may fail to sense the pilot light, causing it to shut down. Ensuring that the thermocouple is functioning properly is essential for your boiler's reliability and safety. Regular maintenance and inspection can prevent such issues and ensure your heating system operates smoothly.

Common Reasons Why Boiler Pilot Lights Go Out

Several factors can cause your furnace pilot light to go out. Issues with the thermocouple may prevent it from detecting the flame, while problems with the gas supply can stop fuel flow entirely. Drafts and poor ventilation can extinguish the flame as well. Additionally, the accumulation of dirt and debris, along with faulty gas valves or regulators, can contribute to pilot light failures. Understanding these factors will help you troubleshoot effectively and maintain your heating system.

Issues With the Thermocouple

The thermocouple in your boilers serves as a critical sensor that detects whether the pilot light is lit. If this sensor fails, it may not properly sense the flame's presence, resulting in the pilot light extinguishing, which in turn prevents the main burner from igniting. Understanding the function of the thermocouple helps you troubleshoot heating issues promptly, ensuring a steady flow of heat during colder months.

Inadequate combustion can occur if the thermocouple becomes dirty or malfunctioning. This buildup can result from debris or soot accumulating around the sensor, which interferes with its ability to function. Keeping the thermocouple clean and well-maintained is essential for the optimal performance of your boiler and can often be resolved using HVAC Supplies available at your local home improvement store.

Furthermore, if you suspect issues with the thermocouple, consider testing its functionality. You can gauge whether it accurately senses the pilot light by observing the pilot indicator; if the light goes out frequently, you may need to replace the thermocouple. By addressing thermocouple issues promptly, you can enhance the reliability of your Radiant Heating and Cooling system, ensuring your home stays comfortable.

- The thermocouple detects the pilot light flame.

- Dirty or damaged thermocouples lead to inadequate combustion.

- Testing and replacing thermocouples ensures efficient heating.

Problems With Gas Supply

Problems with gas supply can significantly affect the operation of your boiler's pilot light. If there's a disruption in gas flow, the pilot light may go out or fail to ignite the main burner. It’s essential to ensure that the gas supply is turned on and that there are no obstructions in the line or issues with the gas valve that could prevent fuel from reaching your boiler.

Environmental factors can sometimes influence gas supply. For example, strong drafts or poor ventilation can impact the pilot light's flame, causing it to flicker or extinguish. Inspecting the area around your boiler for any potential air leaks or blockages can help maintain a stable gas supply, leading to better performance from your heating system.

If you suspect a more serious issue with your gas supply, don’t hesitate to contact a qualified technician for assistance. A professional can help identify problems like low gas pressure or malfunctioning gas valves, ensuring your boiler operates smoothly. By promptly addressing gas supply issues, you not only enhance the reliability of your heating system but also contribute to a safer home environment.

Impact of Drafts and Ventilation

Drafts and poor ventilation are significant factors that can directly impact the reliability of your boiler’s pilot light. If strong drafts are present in your boiler room, they may cause the pilot light flame to flicker or go out altogether. It's crucial to ensure that your boiler area is shielded from wind or external air sources that could disrupt the flame’s stability.

Proper ventilation is essential for maintaining a balanced airflow around your boiler system. If your space lacks sufficient ventilation, it can lead to a buildup of exhaust gases, which may affect combustion efficiency and pilot light functionality. Make sure there are no obstructions near the boiler’s air intake and that all vents are clear and functioning properly to optimize your heating system's performance.

To mitigate the risk of pilot light issues caused by drafts and ventilation problems, consider the following measures:

- Seal any gaps or cracks around the boiler area to prevent drafts.

- Install air barriers to minimize airflow disruption.

- Regularly inspect and clean ventilation ducts to ensure proper airflow.

Accumulation of Dirt and Debris

The accumulation of dirt and debris around your boiler’s pilot light can severely disrupt its functionality. This buildup can obstruct the flame, preventing it from igniting the main burner when needed. If you notice your pilot light frequently going out or flickering, it’s crucial to inspect the area for any signs of obstruction, which can lead to inefficient heating and increased energy costs.

To address this issue, you should regularly clean the pilot light assembly and surrounding components. A simple maintenance routine that includes checking for dust, lint, or soot can greatly enhance the performance of your heating system. If you’re not comfortable doing this yourself, consider reaching out to a professional service to ensure a thorough inspection and cleaning.

Taking precautionary measures to keep your boiler area clean will help maintain a steady and reliable pilot light. By regularly monitoring and cleaning the pilot light assembly, you can prevent potential heating issues and extend the lifespan of your boiler. Don’t overlook this small yet essential step in your home maintenance routine, as it can significantly impact your system's efficiency and safety.

Faulty Gas Valves or Regulators

Faulty gas valves or regulators can be significant contributors to pilot light issues in your boiler. If a gas valve is malfunctioning, it may not allow the proper amount of gas to flow to the pilot light, resulting in an insufficient flame or a complete shutdown. Regularly inspecting these components is essential for maintaining optimal performance in your heating system.

In some cases, a failing gas regulator can also lead to pressure fluctuations, which can directly impact the stability of your pilot light flame. This inconsistency can cause the flame to extinguish unexpectedly, leaving your heating system unable to operate effectively. If you suspect issues with your gas valves, making timely repairs can help restore your boiler's functionality and reliability.

Addressing gas valve or regulator failures promptly is crucial for your safety and the efficiency of your boiler. Consider consulting a professional if you notice any irregularities or suspect a valve may be faulty. They can thoroughly assess the situation, identify the problem, and ensure that your heating system returns to optimal working condition.

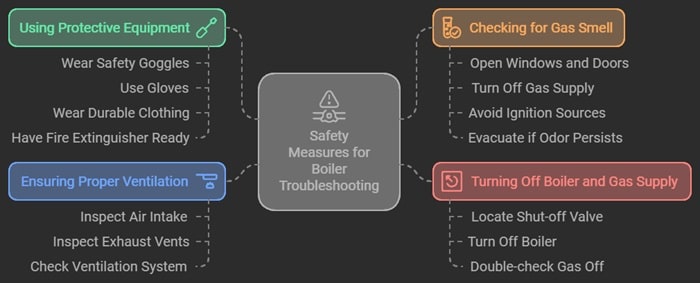

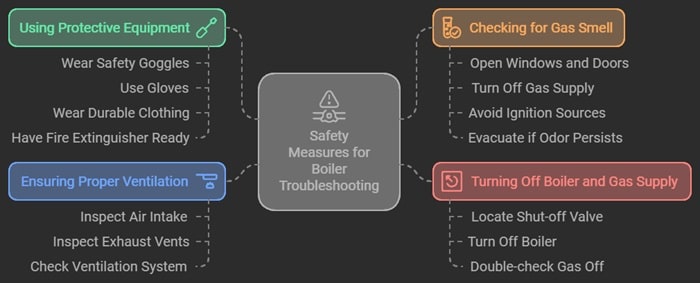

Safety Measures Before Starting Troubleshooting

Before addressing your boiler pilot light issues, ensure your safety by turning off the boiler and gas supply. Verify proper ventilation in the area to avoid gas buildup. Use the appropriate protective equipment to safeguard yourself during the process. Always check for any smell of gas; if detected, evacuate immediately and contact a professional. These precautions create a safe environment for effective troubleshooting.

Turning Off the Boiler and Gas Supply

Before you troubleshoot your boiler pilot light issues, it’s essential to turn off the boiler and the gas supply. This step is critical for ensuring your safety as you work on the heating system. To do this, locate the shut-off valve, which is typically found near the gas meter or on the gas line leading to the boiler.

After shutting off the gas supply, proceed to turn off your boiler. Most units have a clearly marked power switch or a thermostat setting that allows you to stop its operations safely. This precaution helps prevent any accidental ignition while you investigate the pilot light problems.

Always double-check that you've completely turned off the gas before attempting to troubleshoot the boiler. If you notice any lingering smell of gas, avoid using ignition sources like matches or lighters and ventilate the area to prevent gas accumulation. Taking these safety measures seriously will provide you with a secure environment to address your boiler’s pilot light issues effectively.

Ensuring Proper Ventilation in the Area

Proper ventilation is essential when troubleshooting your boiler's pilot light issues. It helps prevent gas buildup, which can be hazardous to your health and safety. Ensuring that the area around your boiler is well-ventilated allows any potential leaks to disperse quickly, minimizing the risk of inhaling gas.

To maintain effective ventilation, inspect your boilerroom for any obstructions near the air intake and exhaust vents. These components should be clear to allow fresh air to enter and exhaust gases to exit freely. If there are barriers, such as furniture or dust accumulation, remove them to promote optimal airflow in the area.

Lastly, regularly check that your ventilation system, including fans and ducts, is functioning properly. Faulty ventilation can contribute to pilot light failures by causing inadequate combustion or unstable flame conditions. By keeping an eye on your ventilation components, you enhance the overall safety and effectiveness of your boiler system.

- Ensure the boiler area is well-ventilated to prevent gas buildup.

- Inspect and remove any obstructions near the air intake and exhaust vents.

- Regularly check ventilation systems to maintain optimal performance.

Using the Right Protective Equipment

When troubleshooting your boiler pilot light issues, using the right protective equipment is essential for ensuring your safety. This includes items such as safety goggles, gloves, and a mask to protect you from any harmful gases or debris while you work. These precautions can prevent minor injuries and provide peace of mind as you handle potentially hazardous materials.

Another important aspect of protective gear is wearing durable clothing. Heavy-duty work clothes can shield your skin from sharp edges and hot components you may encounter during the troubleshooting process. By dressing appropriately, you minimize the risk of injury and create a safer working environment as you inspect and address your boiler’s pilot light problems.

Don’t forget to have a fire extinguisher accessible nearby, especially when working with gas appliances. Having the right equipment on hand allows you to act quickly in case of an unexpected situation. By taking these safety measures seriously, you can focus on resolving your boiler pilot light issues effectively without compromising your well-being.

Checking for the Smell of Gas

Before diving into troubleshooting your boiler’s pilot light issues, it's imperative to check for any smell of gas in the area. If you detect a gas odor, it's critical to act swiftly. Open windows and doors to ventilate the space and turning off the gas supply can prevent potential hazards and is a necessary precaution.

Once you've ensured proper ventilation, avoid using any electrical devices, ignitions sources, or flames. This is essential to minimize the risk of ignition. Take note to stay alert to any lingering odors; if the smell persists, evacuate the area immediately and contact a professional to handle the situation.

Performing a gas odor check should always be part of your safety procedures before troubleshooting boiler pilot light problems. Recognizing this basic yet crucial step ensures a safe environment while you address other issues. Always be prepared to take proper action if you suspect a leak:

- Ventilate the area by opening windows and doors.

- Turn off the gas supply to your heating system.

- Avoid ignition sources and electronic devices.

- If the odor persists, evacuate the area and contact a professional.

Step-by-Step Guide to Relighting a Boiler Pilot Light

To relight your boiler pilot light, you first need to locate the pilot light assembly. This guide will provide instructions for both manual pilot light systems and electronic ignition systems. Additionally, you will learn troubleshooting techniques if the pilot light won't stay lit, ensuring you can effectively address any issues.

Locating the Pilot Light Assembly

To locate the pilot light assembly in your boiler, start by consulting your boiler's manual for specific instructions tailored to your model. Typically, the pilot light is housed near the burner and is easily accessed through a small door or cover on the front of the unit. This assembly usually includes a gas control valve, a thermocouple, and the pilot orifice, so identifying it correctly is crucial for effective troubleshooting.

Once you've identified the location of the pilot light assembly, carefully remove any access panels to avoid damaging components in the process. Ensure you have adequate lighting to clearly see the assembly and any surrounding parts. This careful inspection allows you to check for issues such as dust accumulation or blockages that could impact the pilot light's functionality.

After locating the pilot light assembly, proceed to observe the pilot flame for stability and correct color. A steady blue flame indicates proper operation, while a yellow or flickering flame may suggest issues that need addressing. Understanding where the pilot light assembly is situated empowers you to perform regular maintenance or troubleshooting tasks, enhancing the efficiency of your boilersystem.

Instructions for Manual Pilot Light Systems

To successfully relight a manual pilot light on your boiler, begin by ensuring that the gas supply is turned off. Locate the pilot light assembly, usually marked clearly on the boiler, and remove any access cover if necessary. This initial step is critical for safety, as it prevents gas from accumulating while you work.

Once you've confirmed that the gas is off, wait a few minutes to allow any residual gas to dissipate. Then, set the gas control valve to the "pilot" position. Depress the reset button while using a long lighter or match to ignite the pilot. Keep the button pressed for about 30 seconds after lighting the pilot to allow the thermocouple to heat up and stabilize the flame.

If the pilot light does not remain lit after relighting, it may indicate additional issues, such as a blocked pilot tube or faulty thermocouple. To ensure consistent operation, regularly check for dirt or debris around the pilot light. Following these steps will help maintain your boiler’s efficiency and can prevent future complications:

- Turn off the gas supply.

- Locate the pilot light assembly.

- Set the gas control valve to "pilot" and light the pilot.

- Check for and clean any blockages or issues if the light does not stay lit.

Relighting Electronic Ignition Systems

To relight an electronic ignition system, start by verifying that the gas supply is on. Electronic ignition systems only light the burner when heat is required, so ensure that the thermostat is calling for heat. If the system is not functioning, check the power source and any circuit breakers to confirm that electricity is supplied to the unit.

Next, locate the reset button on the gas control unit, which typically needs to be pressed to initiate ignition. Carefully follow your manufacturer's instructions for resetting the electronic ignition system, as each model may have specific guidelines. If done correctly, the system should attempt to ignite the burners, indicated by a clicking sound as the igniter activates.

If the burner fails to ignite after following these steps, be prepared to investigate further. Consult the boiler's manual for troubleshooting procedures specific to your model. Ensure the appliance is free of blockages, and if problems persist, it may be wise to contact a professional technician for assistance:

- Confirm the gas supply is on and functioning.

- Check the power source and reset the ignition system.

- Consult the manual for additional troubleshooting steps.

Troubleshooting if the Pilot Light Won't Stay Lit

If the pilot light won't stay lit, you may be dealing with issues related to the thermocouple. This component is designed to detect whether the pilot light is on, and if it’s not functioning properly, it could cause the pilot light to shut off. Regular maintenance of the thermocouple can help ensure that it accurately senses the light, preventing disruptions to your heating system.

Another common cause for a pilot light that won't stay lit is insufficient gas supply. You should check to ensure that the gas valve is fully open and that the gas line is clear of any obstructions. If there are no visible blockages and the supply seems stable, you might want to evaluate if there are any pressure-related issues, as fluctuations can compromise the flame.

Lastly, it’s essential to inspect the pilot light assembly for dirt or debris that could obstruct the flow of gas. If contamination is present, cleaning the area around the pilot light can help restore functionality. Keeping your boiler and its components clean promotes optimal performance and ensures that the pilot light remains lit, thus maintaining your home’s warmth and comfort.

Preventing Future Pilot Light Issues

To prevent future boiler pilot light issues, consider scheduling regular boiler maintenance. This proactive approach ensures your system operates efficiently. Keeping the pilot light area clean and clear minimizes obstructions while checking for proper ventilation around the boiler promotes safety. Additionally, regularly monitoring gas pressure and supply helps maintain consistent performance, allowing you to enjoy a warm and comfortable home.

Scheduling Regular Boiler maintenance

Scheduling regular boiler maintenance is essential for keeping your heating system running efficiently and safely. Regular maintenance checks allow you to identify potential issues before they escalate into costly repairs, ensuring your boiler operates optimally. Consider arranging for a qualified technician to inspect vital components, including the pilot light and gas supply, to enhance your home’s comfort during colder months.

During maintenance sessions, technicians can clean and service the pilot assembly, ensuring that the flame remains stable and efficient. This proactive approach not only helps prevent pilot light issues but also extends the lifespan of your boiler. Engaging in routine checks provides peace of mind, knowing your heating system is ready to function properly when you need it most.

Additionally, regular boiler maintenance can improve energy efficiency, resulting in lower utility bills. By investing in preventative care, you can address minor problems like dirt buildup or gas pressure fluctuations before they become significant hassles. This ensures that your boiler continues providing reliable warmth and comfort, giving you confidence in your home's heating system.

Keeping the Pilot Light Area Clean and Clear

Regular cleaning of the pilot light area is essential to keeping your boiler pilot light functioning efficiently. Dust and debris can obstruct the pilot flame, preventing it from igniting the main burner effectively. You can use a soft brush or vacuum to remove any buildup around the pilot light assembly, ensuring that your system operates safely and avoids unnecessary breakdowns.

It's also important to inspect the combustion area for any signs of leaks or corrosion. This thorough examination allows you to identify potential hazards early on. If you observe any rust or deterioration, consider contacting a professional technician for further assessment, as these issues can compromise the safety and efficiency of your heating system.

Creating a consistent maintenance routine helps ensure the pilot light area remains clean and clear. Make it a habit to check the area during seasonal maintenance or whenever you experience pilot light issues. By doing so, you reduce the risk of pilot light failures and enhance the overall reliability of your boiler, allowing your home to maintain a comfortable temperature during colder months.

Checking for Proper Ventilation Around the Boiler

Checking for proper ventilation around your boiler is vital in preventing pilot light issues. Adequate airflow ensures your heating system operates efficiently and minimizes the risk of carbon monoxide build-up. Regularly inspect the area around your boiler to ensure there are no obstructions, such as furniture or debris, that could hinder airflow.

Make it a practice to clear any potential blockages near air intakes and exhaust vents. Proper ventilation not only supports stable pilot light operation but also enhances overall system efficiency. By maintaining a clean and open environment for your boiler, you can help prevent future heating issues and extend the lifespan of your equipment.

To ensure ongoing effectiveness, consider performing routine checks on your boiler's ventilation system. This includes looking for signs of wear and tear and ensuring all vents are functioning correctly. Maintaining proper ventilation around your boiler is an essential step to safeguard your system and keep your home warm and comfortable:

- Inspect the boiler area regularly for obstructions.

- Clear air intakes and exhaust vents of debris.

- Check ventilation systems for functionality.

Monitoring Gas Pressure and Supply Regularly

Monitoring gas pressure and supply is essential for the reliable operation of your boiler's pilot light. Fluctuations in gas pressure can lead to a weak pilot flame or even cause it to extinguish. Regular checks on your gas supply lines and valves can prevent potential interruptions to your heating system, ensuring a consistent flow of fuel to maintain the pilot light's stability.

It's advisable to familiarize yourself with your boiler's pressure requirements, as many models operate optimally within a specific range. If you notice irregularities, such as a decrease in heating performance or unusual pilot light behavior, measure the gas pressure using a manometer. Keeping records of any fluctuations can help you identify patterns, making troubleshooting more effective when challenges arise.

Implement these simple habits to ensure your gas pressure remains stable and your pilot light operates correctly:

- Regularly check the gas supply connections for leaks.

- Monitor the pressure gauge and ensure it aligns with your boiler’s specifications.

- Address any observed irregularities promptly by consulting a professional.

Knowing When to Seek Professional Help

Identifying problems that require expert assistance is crucial for maintaining your boiler’s efficiency and safety. In this section, you will learn about the benefits of professional boiler servicing, including thorough inspections and timely repairs. Additionally, we’ll cover how to choose a qualified heating technician, ensuring that your boiler receives the care it needs for optimal performance.

Identifying Problems That Require Expert Assistance

When troubleshooting your boiler's pilot light issues, it's important to recognize when a situation exceeds your expertise and requires professional assistance. If you've followed basic troubleshooting steps—such as checking the gas supply and relighting the pilot—yet the light still won't stay on, it may indicate a deeper issue like a failing thermocouple or a problematic gas valve. In such cases, seeking help from a qualified technician can save you time and ensure your system operates safely and efficiently.

Another sign that you should consult a professional is the presence of a gas odor in your home. If you smell gas, this could indicate a dangerous leak or malfunction within the boiler system. Under these circumstances, immediately vacate the premises and contact emergency services. A certified technician will have the tools and knowledge necessary to locate and rectify gas leaks, protecting you and your family from serious risks.

Always remember, routine maintenance is a proactive way to avoid future pilot light problems. If you frequently experience issues with your boiler, consider scheduling a comprehensive service with a professional technician. They can conduct thorough inspections, clean critical components, and ensure that the entire system operates correctly, providing you with peace of mind during the colder months:

- Recognize signs of failure beyond simple troubleshooting.

- Act immediately if you detect a gas odor.

- Invest in regular maintenance to prevent future issues.

The Benefits of Professional Boiler Servicing

Investing in professional boilerservicing is essential for maintaining the efficiency and safety of your heating system. A qualified technician can conduct thorough inspections and routine maintenance, identifying potential issues before they escalate into costly repairs. This proactive approach not only saves you money in the long run but ensures consistent warmth throughout your home during the colder months.

When you choose professional servicing, you're also benefiting from expert knowledge and experience. Technicians are trained to handle complex systems and can troubleshoot problems that may be beyond your understanding. For example, they can accurately diagnose issues related to the thermocouple or gas valves, ensuring that your boileroperates smoothly and reducing the chances of pilot light malfunctions.

In addition to technical skills, professionals have access to specialized tools and equipment that facilitate thorough servicing. By regularly scheduling these check-ups, you ensure your boiler remains in optimal condition, prolonging its lifespan and enhancing its efficiency. This commitment to maintenance ensures you're not only comfortable in your home but also minimizes the risk of emergencies related to your heating system.

How to Choose a Qualified Heating Technician

When selecting a qualified heating technician, look for certifications and licenses that confirm their expertise. A certified technician demonstrates the necessary knowledge and training to handle various boiler systems properly. Inquire about their experience with the specific type of boiler you have, as familiarity with your system type can significantly influence the quality of service provided.

Checking online reviews and testimonials can provide additional insights into a technician's reliability and skill. Ask for references from previous clients and take the time to contact them for feedback. This approach helps you gauge the technician's performance and customer service, ensuring you're making an informed decision about your boiler maintenance needs.

Lastly, discuss pricing and service guarantees before hiring a technician. Transparency in pricing helps you understand what to expect regarding costs, while a warranty on services performed offers peace of mind. Prioritize technicians who provide upfront estimates and outline their services clearly, as this indicates professionalism and accountability in their work:

- Look for certifications and licenses to verify expertise.

- Check online reviews and customer testimonials for reliable feedback.

- Discuss pricing and service guarantees to ensure transparency.

Conclusion

Effectively troubleshooting boiler pilot light issues is crucial for maintaining your heating system's efficiency and safety. Understanding the common causes, such as thermocouple malfunctions and gas supply problems, empowers you to act quickly and address potential hazards. Regular maintenance, including cleaning and monitoring gas pressure, ensures optimal operation and increases your comfort during colder months. By prioritizing these steps, you safeguard your home against unexpected heating failures and promote a reliable heating solution.

Resources:

Learn about HVAC

Learn about boilers