When was the last time your boiler system left you in the cold? Many homeowners experience this frustrating issue, often leading to a reset of their system. In this guide, you’ll learn when and why to reset your boiler, essential safety precautions to take, and a step-by-step process for safely resetting your boiler. By understanding these steps, you can ensure your boiler operates efficiently and effectively, eliminating unnecessary interruptions to your home’s heating. Plus, we'll touch upon troubleshooting and when it might be time to call in a professional technician for further HVAC assistance.

Understanding When and Why to Reset Your Boiler System

Recognizing the signs your boiler requires resetting is essential for efficient operation. Common causes of boiler lockouts include sensor issues, ventilation problems, and leaks. Understanding why these issues occur will help you implement safe resetting practices. In the following sections, you will learn how to identify these signs and reset your system effectively.

Signs Your Boiler Needs Resetting

One clear sign that your boiler needs resetting is when you notice irregular pressure levels. A Vaillant boiler, for instance, typically operates within a specific pressure range. If you observe the pressure gauge dropping below the recommended levels, this may indicate a fault that requires attention. Inadequate pressure can lead to inefficient heating and may trigger a lockout, necessitating a reset.

Another indication that your boiler may require a reset is the presence of error codes on the display panel. Most modern boilers, including those used in HVAC systems, have built-in diagnostic tools that provide alerts for various issues. If you see an error message, taking the time to consult your user manual can help you understand the problem. Some common errors relate to ignition failure or sensor malfunctions that may need resolving through a system reset.

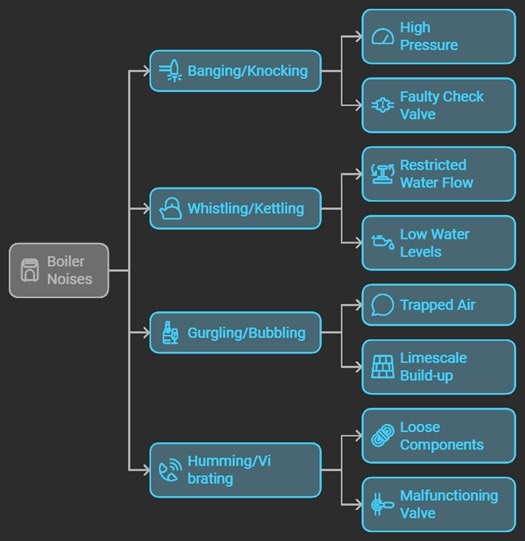

Also, listen for unusual noises from the boiler system. Sounds such as gurgling, banging, or whistling can signal potential issues within the tank or heating components. These noises may occur due to blockages or air trapped in the system. Detecting such irregularities early on can save you from larger complications, reinforcing the importance of understanding when and why to reset your boiler.

Common Causes of Boiler Lockouts

One of the most common causes of boiler lockouts is issues related to the pressure valve. If the pressure in your boiler drops too low or rises too high, it can disrupt the central heating system's efficiency, leading to a lockout. A faulty pressure valve may need recalibration or replacement to restore smooth operation.

Another frequent reason for a boiler lockout involves sensor problems. Sensors play a vital role in monitoring the system's performance and ensuring it operates safely. If you encounter a situation where your boiler is indicating a lockout due to a sensor malfunction, you should check the connections and functionality of the sensors to ensure they are working properly, as they directly impact energy efficiency.

Ventilation issues can also trigger boiler lockouts. Inadequate airflow can prevent your heat pump from functioning as needed, resulting in operational failures. Make sure vents are free of blockages to maintain optimal airflow, as this can prevent many problems from arising in the first place, ensuring your central heating system runs smoothly and efficiently.

Importance of Safe Resetting Practices

Prioritizing safe resetting practices for your boiler is crucial to maintaining the integrity of your heating system. A boiler reset can often be a straightforward process, but if done improperly, it can lead to further malfunctions or even safety hazards. For example, consistently experiencing boiler lockout situations without understanding the causes can result in damper issues or radiator malfunctions, jeopardizing your home’s comfort and safety.

When you proceed with a boiler reset, it's important to carefully observe the manufacturer’s guidelines. Each system may have its specific reset button or sequence which you should follow to prevent unnecessary strain on the components. Neglecting these instructions can cause repetitive lockouts, wasting energy and time while potentially damaging parts of your heating system.

Understanding when to confidently reset your boiler also prompts timely attention to emerging problems. For instance, if you reset your system after noticing irregular noises or error codes, you may identify underlying issues before they escalate. This proactive approach not only saves you potential repair costs but also ensures your heating system operates efficiently, keeping your home warm and comfortable.

Safety Precautions Before Resetting Your Boiler

Before you proceed to reset your boiler system, it is critical to ensure safety by checking for any natural gas leaks or odors that may indicate a hazardous situation. Proper ventilation around the boiler area is also essential to prevent the buildup of harmful gases. Additionally, reading the manufacturer’s manual provides guidance specific to your boiler model, ensuring both safety and efficiency.

Checking for Gas Leaks or Odors

Before resetting your boiler system, it is essential to check for gas leaks or any unusual odors that may indicate a problem. If you detect a sulfur or rotten egg smell, this is a clear sign of a gas leak, and you should take immediate action. It's vital to turn off the furnace and refrain from operating any electrical devices in the area until the situation is assessed by a professional.

A reliable method to check for gas leaks is to use a mixture of soapy water applied to the gas lines and connections. If bubbles form, this is an indication of a leak. In this case, contact an emergency HVAC service right away to address the issue before proceeding with any boiler adjustments.

Also, ensure that your boiler area is well-ventilated to facilitate any gas dissipation. Proper airflow can help prevent potential gas buildup, which creates a hazardous environment not only for you but also for your family. Regularly changing your oil air filter and inspecting ventilation can further reduce risks and ensure the efficient operation of your heating system:

- Check for any noticeable gas odors around the boiler.

- Use soapy water on gas connections for leak detection.

- Contact emergency HVAC service if a leak is detected.

- Ensure proper ventilation in the boiler area.

- Maintain the air filter to prevent operational issues.

Ensuring Proper Ventilation

Ensuring proper ventilation around your boiler is essential for safe operation and effective combustion of fuel. Adequate airflow helps to prevent the buildup of potentially harmful gases, which could lead to hazardous situations both for you and your HVAC system. Regular inspection of the area surrounding the boiler helps to identify any obstructions that may impede airflow, allowing you to maintain an efficient heating system.

Keeping your thermostat settings optimized also plays a role in ensuring proper ventilation. If your thermostat is set incorrectly, it may cause the boiler to work harder than necessary, which can lead to overheating and increased gas emissions. Regularly inspect your thermostat and make adjustments as needed to ensure that your heating system is functioning efficiently and safely.

Finally, you should also check your circuit breaker to make sure your boiler is receiving consistent power. If the circuit breaker trips often, this may indicate underlying issues that could affect both ventilation and the performance of HVAC Parts. Addressing any electrical concerns in conjunction with your ventilation checks will help maintain the overall efficiency and safety of your boiler system:

- Inspect the area around your boiler for obstructions.

- Ensure the thermostat is set correctly to avoid inefficiencies.

- Check the circuit breaker for a consistent power supply.

- Verify that vents are free from debris and blockages.

- Regularly service your HVAC parts to maintain optimal performance.

Reading the Manufacturer’s Manual

Reading the manufacturer’s manual is a critical step before resetting your boiler system. This document provides specific instructions tailored to your unit, ensuring you fully understand the functionalities and requirements that pertain to your model. Familiarize yourself with the manual safeguards against potential errors that could lead to further complications in your heating system.

The manual often contains crucial information about resetting procedures, including safety protocols, reset button locations, and troubleshooting tips. For instance, if you have a boiler that connects with Radiant Heating and Cooling systems, it’s important to follow the guidelines to ensure compatibility and performance. Knowing these details can help you make informed decisions, avoiding costly mistakes in your HVAC Supplies.

Furthermore, the manufacturer's manual typically outlines maintenance schedules and part specifications, further supporting the longevity of your boiler system. Proper adherence to these guidelines can improve efficiency and prevent future breakdowns. By building a solid understanding of your boiler's operating instructions, you enhance your ability to address issues promptly and effectively:

- Familiarize yourself with the specific reset instructions.

- Understand safety protocols to protect yourself and your equipment.

- Research maintenance schedules are provided in the manual.

Step-by-Step Guide to Safely Resetting Your Boiler

To safely reset your boiler system, start by turning off the boiler and the power supply. Next, locate the reset button, typically found on the control panel. Once you've identified it, press and hold the button for a few seconds before restarting the boiler. Finally, the performance must be monitored to ensure it operates efficiently. This guide will walk you through each step, ensuring a safe and effective reset process.

Turning Off the Boiler and Power Supply

Turning off your boiler and its power supply is the first critical step in safely resetting your boiler system. Start by locating the main power switch or circuit breaker that controls the boiler’s electricity. This ensures all components are safely powered down before attempting any resetting process.

Once you've turned off the power, it's advisable to wait a few moments to allow any residual power to dissipate. This step is essential to prevent any electrical shocks or unintended activation of the heating system during the reset process. Remember, ensuring complete deactivation protects both you and your boiler from potential malfunctions.

After confirming that the system is entirely off, you can proceed confidently with the reset. Starting with a powered-down boiler reduces the risk of errors and ensures any sensitive components can be reset without stress. This careful approach not only safeguards your equipment but also enhances the overall effectiveness of the heating system once reactivated.

Locating the Reset Button

Locating the reset button on your boiler system is a straightforward process but essential for effective resetting. Most boilers feature a clear and accessible reset button typically found on the control panel. Familiarize yourself with this area, as it will help you efficiently troubleshoot and resolve any issues that may arise.

Once you've identified the control panel, look for a button labeled "Reset" or sometimes indicated with a circular arrow symbol. It's often distinguished from other buttons, making it easier to spot. If you have difficulty finding it, consult your manufacturer's manual for specific guidance on the location of the reset button tailored to your boiler model.

Before you move forward with resetting the system, ensure you've turned off the power. Once you locate the button, you’ll be ready to press and hold it for a few seconds, after which you can restart your boiler. Knowing how to find and properly utilize the reset button is critical in maintaining efficient operations of your heating system:

- Identify the control panel on your boiler.

- Locate the reset button, labeled typically as "Reset."

- Ensure the boiler is powered down before pressing the reset button.

Pressing and Holding the Reset Button

Once you have located the reset button on your boiler, the next step is to press and hold it. Typically, you will find this button on the control panel, where it is clearly marked. Holding the reset button firmly for a few seconds sends a signal to the system to reinitialize, allowing it to restart and resume normal operations.

It’s essential to maintain pressure on the reset button until you notice a change; this may include lights illuminating on the control panel or hearing the system activate. This action helps to clear any lockout conditions that may have led to disruptions in your heating system. Understanding the feedback from your boiler can assist you in determining whether the reset was successful.

After releasing the reset button, take a moment to monitor your boiler's performance. Check for any unusual noises or error codes on the display panel. Keeping a close eye on these indicators allows you to address any emerging issues promptly, ensuring your boiler operates smoothly and efficiently after the reset process.

Restarting the boiler and Monitoring Performance

After successfully pressing and holding the reset button, it’s time to restart your boiler. Restore power to the system by flipping the main power switch or circuit breaker back on. Once the boiler is powered, you should hear the system activate, indicating that it is resuming operations. Observing this initial response is crucial to ensuring that the reset was effective.

As the boiler begins its heating cycle, pay attention to how it operates. Listen for normal sounds, such as the steady humming of the pump or the gentle flow of water within the system. If you hear any irregular noises, like banging or clanging, it could indicate a problem that requires your immediate attention. Monitoring these sounds will help you catch any issues early, preventing further complications in your heating system.

Keep an eye on the display panel for error codes or pressure fluctuations during the initial warming period. If the pressure gauge returns to a stable level within the recommended range, this is a positive sign your boiler is performing well. Continuously check these indicators over the next few hours and be proactive about addressing any signs of malfunction, as this will help maintain the efficiency and safety of your boiler system in the long run.

Troubleshooting if the Boiler Doesn’t Reset

If your boiler fails to reset, it's crucial to systematically troubleshoot the underlying issues. Start by identifying any error codes displayed, as these provide direct insight into the problem. Next, check the boiler pressure levels to ensure they are within the recommended range. Finally, inspect for blockages or airlocks that could impair system functionality. Assessing these key areas will help you determine the necessary steps to restore your boiler's operation.

Identifying Error Codes on the Display

Identifying error codes on your boiler's display can provide crucial insights into the issues affecting your heating system. When you encounter a lockout, the first step is to look for specific codes that appear, as these codes typically indicate what might be malfunctioning. Modern boilers often have built-in diagnostic capabilities, making it easier for you to pinpoint problems without extensive troubleshooting.

Once you've noted the error code, it's vital to refer to your manufacturer's manual, which will often provide a comprehensive list of error codes along with their corresponding meanings. This resource can guide you on whether you're dealing with a minor issue, such as a temporary sensor malfunction, or something more serious that requires professional intervention. Understanding these codes enables you to communicate effectively with HVAC professionals if needed.

Additionally, if multiple error codes appear, it could signal a more complex issue within the boiler system. Focus on the most critical error or the one that recurs most frequently, as addressing this first can prevent further complications. By staying informed about your system's diagnostics and acting quickly on error readings, you enhance your ability to maintain a functional and efficient heating system:

- Look for error codes displayed on the boiler.

- Consult the manufacturer’s manual for meanings of codes.

- Address the most critical error to prevent further issues.

Checking Boiler Pressure Levels

Checking the boiler pressure levels is an important step when troubleshooting why your boiler doesn’t reset. You should start by locating the pressure gauge, typically positioned on the front of your boiler. Ensure that the pressure reading is within the recommended range, usually between 1 and 1.5 bar when the system is cold; readings below this range may indicate a need for a refill or a potential issue.

When the pressure levels are too low, you're likely to experience issues with heating efficiency, prompting a lockout situation. If the gauge shows low pressure, you can add water to the system via the filling loop, following your manufacturer’s guidelines. It’s crucial to monitor this adjustment carefully, as excessive pressure can lead to further complications, including leaks or damage to the boiler itself.

If your boiler pressure appears to be within the correct range yet it still won’t reset, you might need to consider other factors affecting system performance. These could include trapped air pockets or blockages in your heating system. Therefore, paying close attention to your boiler's pressure levels allows you to identify and address problems early, ensuring reliable heating throughout your home.

Inspecting for Blockages or Airlocks

Inspecting for blockages or airlocks is a crucial step in troubleshooting when your boiler doesn’t reset. If you notice that the heating system isn’t functioning as it should, these issues may be obstructing the flow of water or steam, leading to inefficiencies. Inspect pipes, radiators, and valves for any signs of obstructions that could prevent proper circulation, ensuring that your boiler operates smoothly.

To check for airlocks, you can bleed the radiators by releasing trapped air, which often manifests as uneven heating or cold spots. A simple tool like a radiator key allows you to open the valve, letting out air until water starts to flow. Performing this maintenance helps restore the system's ability to circulate fluid efficiently, which is essential for maintaining consistent heating in your home.

If you suspect a blockage, a more thorough investigation may be required. Pay close attention to any unusual noises, like gurgling sounds within the boiler or pipes, as these can indicate trapped air or blockage issues. By staying attentive to these signals and addressing them promptly, you can significantly improve your boiler's performance and prevent further complications in the heating system.

When to Contact a Professional Technician

If you experience persistent boiler issues after resetting or if you notice unusual noises or smells from your boiler, it's time to contact a professional technician. Regular maintenance and servicing play a vital role in keeping your heating system operating efficiently. This section will address when to seek expert help, ensuring your boiler remains safe and effective for your home.

Persistent Boiler Issues After Resetting

If your boiler continues to show persistent issues after attempting a reset, it may indicate underlying problems that need professional attention. For instance, if error codes remain on the display, or if the unit repeatedly locks out, this suggests that the resetting process has not resolved the root cause of the malfunction. Addressing these recurring issues early can prevent more extensive damage or costly repairs in the future.

Another sign that you should contact a professional technician is if you hear unusual noises coming from your boiler, such as banging or gurgling sounds, even after a reset. These noises can often point to airlocks or blockages within your system, which may not be easy to fix without specialized knowledge. A technician can help diagnose the exact cause and recommend appropriate solutions to restore your boiler's efficiency.

In some cases, persistent boiler problems may relate to more complex issues, such as sensor failures or faulty components that require expert intervention. If you find yourself resetting your boiler frequently without lasting improvements, reaching out to a qualified HVAC technician is the best course of action. They can perform a comprehensive inspection and ensure that your heating system operates safely and efficiently, providing peace of mind for your home’s comfort.

Unusual Noises or Smells From the boiler

If you notice unusual noises emanating from your boiler, such as banging, gurgling, or hissing sounds, it could signal a malfunction within the heating system. These noises often suggest issues like airlocks, blockages, or even problems with the pump. Paying attention to these sounds can help you identify the problem early, which may prevent further complications.

Similarly, if you detect any strange smells coming from your boiler, such as a sulfur or rotten egg odor, this may indicate a gas leak. It’s crucial to act immediately if you sense these odors by turning off the boiler and contacting a professional technician. Safety should be your priority; ignorable signs can lead to significant hazards for you and your household.

Taking quick action in response to unusual noises or smells can save you from extensive damage and costly repairs down the line. If the problem persists despite your resets or attempts to troubleshoot, consulting with an HVAC expert is the best course of action. Their expertise can provide a thorough evaluation and ensure the safe operation of your boiler system:

- Identify unusual noises, like banging or hissing.

- Check for any strange smells indicating potential gas leaks.

- Contact a professional if problems persist after self-troubleshooting.

Regular Maintenance and Servicing Importance

Regular maintenance and servicing of your boiler are essential to ensure optimal performance and longevity. Scheduling routine inspections allows trained technicians to identify potential issues early, preventing more complex problems from developing. A well-maintained boiler system not only operates more efficiently but also reduces the risk of unexpected breakdowns that could leave you without heat when you need it most.

Many homeowners underestimate the value of consistent servicing, thinking that resetting the boiler is sufficient to keep it running smoothly. However, regular maintenance goes beyond simple resets; it includes checks for issues such as pressure levels, airlocks, and gas supply safety. Addressing these components through professional service can enhance your heating system's reliability and safety, saving you time and money in the long run.

Moreover, routine maintenance is vital in adhering to manufacturer guidelines, which often stipulate specific service intervals to keep warranties intact. By working with a professional technician, you ensure your boiler system is always in compliance with safety standards and operating as intended. This proactive approach not only gives you peace of mind but also helps maintain a comfortable home environment throughout the colder months.

Preventative Measures to Avoid Future Boiler Resets

Scheduling annual boiler inspections is vital for maintaining optimal performance and preventing future lockouts. Keeping the boiler area clean and accessible ensures efficient airflow, while regularly monitoring system performance helps you identify potential issues early. Each of these measures plays a crucial role in extending your boiler's lifespan and minimizing the need for frequent resets.

Scheduling Annual Boiler Inspections

Scheduling annual boiler inspections is crucial for maintaining the efficiency and safety of your heating system. By having a qualified technician check your boiler regularly, you can identify potential issues before they escalate into costly repairs or operational breakdowns. These inspections can help ensure your boiler runs smoothly and efficiently throughout the heating season.

During an annual inspection, a technician typically assesses key components such as pressure levels, safety controls, and ventilation. This thorough examination helps you understand your boiler's condition and allows for timely adjustments or repairs. By addressing any detected problems early, you can significantly reduce the likelihood of experiencing lockouts that lead to the need for frequent resets.

Incorporating regular boiler inspections into your maintenance routine not only extends the lifespan of your system but also keeps your home comfortable and safe. Consider setting a reminder to schedule these inspections at the start of each heating season. By being proactive, you can effectively minimize unexpected boiler issues, ensuring a consistently warm environment in your home:

- Schedule inspections annually with a qualified technician.

- Assess key components such as pressure levels and ventilation.

- Address detected issues promptly to prevent larger problems.

- Set reminders for inspections at the beginning of each heating season.

- Enjoy a more efficient and reliable boiler system.

Keeping the Boiler Area Clean and Accessible

Maintaining a clean and accessible boiler area is essential for optimal performance and safety. Regularly remove dust, debris, and any obstructions that may accumulate around the boiler. Keeping the space tidy not only facilitates proper airflow but also allows you to easily identify any potential issues during routine checks.

Ensure that there is sufficient space around the boiler for ventilation and maintenance. A clutter-free environment helps prevent overheating and reduces the risk of fire hazards. Make it a habit to periodically inspect the area for any items that may block ventilation, as this proactive approach can save you from troubleshooting difficulties in the future.

Additionally, consider organizing the boiler area by placing tools and supplies for servicing within reach. This accessibility allows you to conduct basic maintenance tasks with ease, such as checking pressure levels or inspecting valves. By prioritizing the cleanliness and organization of your boiler space, you empower yourself to handle potential issues before they escalate into costly repairs or unexpected breakdowns.

Monitoring System Performance Regularly

Regularly monitoring your boiler system’s performance is essential for maintaining its efficiency and preventing unexpected lockouts. By keeping an eye on key indicators such as pressure levels, water temperature, and operational noises, you can catch potential issues before they escalate. This proactive approach not only saves you from costly repairs but also enhances the overall lifespan of your boiler.

You should establish a routine for checking your boiler system—ideally, monthly or quarterly. Start by inspecting the pressure gauge to ensure it remains within the recommended range. If you notice fluctuations or irregularities, addressing them early can prevent more severe complications down the line, ensuring your heating system operates smoothly.

In addition to monitoring pressure, pay attention to any unusual sounds or error codes that may arise. Identifying these issues promptly allows you to take the necessary steps for resolution, whether it involves a simple reset or seeking professional help. By maintaining a consistent monitoring schedule, you empower yourself to manage your boiler system effectively, enhancing comfort in your home:

- Regularly inspect the pressure gauge.

- Listen for unusual noises indicating potential issues.

- Look out for error codes on the control panel.

- Address irregularities immediately to maintain efficiency.

- Establish a consistent monitoring schedule for best results.

Conclusion

Understanding the step-by-step guide to safely resetting your boiler system is essential for maintaining efficiency and safety. By following the outlined procedures—turning off the boiler, locating and utilizing the reset button, and monitoring performance—you can address common issues effectively. This proactive approach not only prevents future lockouts but also safeguards your heating system against potential hazards. Prioritizing these safe resetting practices ensures your home remains comfortable and your boiler operates optimally at all times.

Resources:

Learn about HVAC

Learn about boilers