Is your boiler not heating your home or providing hot water as it should? You're not alone; many homeowners face common boiler issues that can be frustrating. In this easy boiler troubleshooting guide, you will learn how to tackle problems such as no heat or hot water, boiler leaks, and unusual noises. By following these steps, you’ll gain confidence in handling minor repairs, potentially avoiding costly technician visits while ensuring your system remains within warranty guidelines. Let’s dive into how you can manage these common issues effectively and keep your home comfortable.

Understanding Your Boiler System

Your boiler system consists of essential components, including the centrifugal fan, which plays a vital role in circulating warm air throughout your home. Understanding how your boiler heats your space is crucial to identifying issues such as water damage, soot buildup, or carbon monoxide leaks. Regular check-ups are important to maintain efficiency and safety, helping to prevent severe complications and ensure your heating system runs smoothly.

Key Components of a Boiler

The heat exchanger is a crucial component of your boiler, designed to transfer heat from the combustion gases to the water within the system efficiently. This process allows warm water to circulate throughout your home, ensuring that each room receives adequate heat. Regular furnace maintenance can prevent the heat exchanger from malfunctioning, which can lead to various heating issues and increased energy costs.

The condenser is another key element that works alongside the heat exchanger. It collects and cools the exhaust gases, allowing for the efficient reuse of energy within the boiler system. If your boiler is not functioning properly, examining the condenser for dust buildup or clogs is a practical step to improve performance, as these obstructions can significantly impact heating efficiency.

Finally, maintaining clean components is essential for optimal boiler operation. Dust and debris can accumulate in various parts of your boiler, including the heat exchanger and condenser. Regular cleaning and inspections will help you avoid serious problems while keeping your heating system running smoothly and efficiently. By understanding these components and their functions, you can take proactive steps to address common boiler issues before they escalate.

How a Boiler Heats Your Home

Your boiler heats your home through a straightforward process involving flames and water. When you set your thermostat, it signals the boiler to ignite the burner, creating a flame that heats the water supply. This heated water then circulates through pipes, delivering warmth to each radiator in your home, ensuring a comfortable environment during colder months.

The circulator pump plays a critical role in this heating process. It is responsible for moving the hot water throughout your home’s heating system, efficiently delivering warmth to every room. If you notice uneven heating, it could indicate an issue with the circulator pump, which may need inspection to ensure continuous and effective operation.

Proper ventilation is essential for your boiler to function safely and efficiently. The exhaust gases produced during the heating process must be vented outside, preventing dangerous buildup in your home. Regularly checking the ventilation system, along with the fuse, can help you identify potential issues early, ensuring your home remains safe and comfortably warm throughout the heating season.

Importance of Regular Check-Ups

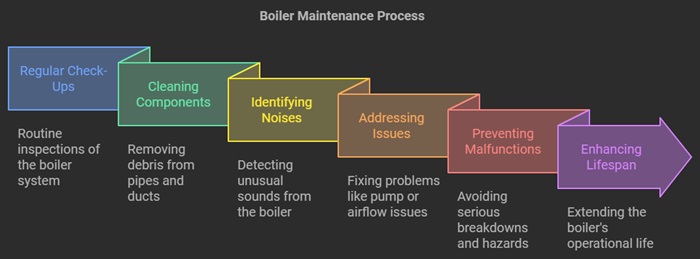

Regular check-ups on your boiler system are essential for maintaining efficiency and avoiding expensive repairs. Over time, components such as pipes and ducts can accumulate debris, causing blockages that may affect your central heating’s performance. These check-ups help catch potential issues early, ensuring that your system operates smoothly and uses energy efficiently.

Additionally, routine inspections can help you identify unusual noises coming from your boiler. These sounds often indicate underlying problems, such as a failing circulator pump or airflow issues. Addressing these noises promptly can prevent more serious malfunctions that may lead to safety hazards or comfort issues in your home.

By committing to regular check-ups, you enhance the lifespan of your boiler while saving on energy costs. A well-maintained system runs more effectively, providing consistent heating and reducing your overall energy consumption. Don’t wait for a breakdown—schedule your boiler inspection today to ensure comfort and efficiency all winter long:

- Regular cleaning of components.

- Early identification of noises.

- Improved efficiency and energy savings.

- Prevention of serious malfunctions.

- Enhanced lifespan of the boiler system.

Troubleshooting No Heat or Hot Water

If your heating system is not producing heat or hot water, several key areas need your attention. Start by inspecting the thermostat settings to ensure they are set correctly. Next, verify that the power supply connections are intact and functioning. Checking the pilot light or ignition system is crucial for proper combustion. Lastly, examine the pressure gauge to ensure it maintains the right levels for optimal airflow. These steps will help you diagnose common issues affecting your furnace or heat pump performance.

Inspecting Thermostat Settings

When troubleshooting your boiler issues, the first step is to inspect your thermostat settings. Ensure that your thermostat is set to a temperature that is higher than the current room temperature. If you have a smart thermostat, double-check the settings to confirm that it is correctly programmed and connected to your Wi-Fi network. Incorrect settings can prevent the system from functioning properly, leading to a lack of heat or hot water.

If the thermostat indicates the correct settings and you are still experiencing issues, it's wise to consider possible malfunctions. A faulty thermocouple can play a significant role in the system's performance by preventing the burner from igniting. In this case, consulting with an HVAC technician may be beneficial, as they can quickly diagnose and remedy any underlying problems associated with your boiler's thermostat and its components.

Remember that your thermostat is the brain of your heating system, and ensuring it operates correctly is essential for your comfort. Regularly inspect and clean your thermostat to prevent dust and debris buildup. This proactive approach can help maintain accurate temperature readings and ensure a longer lifespan for both your thermostat and the entire heating system. If you've checked the settings and everything appears normal, consider these steps for troubleshooting:

- Verify thermostat settings.

- Inspect connections for power supply.

- Check for a faulty thermocouple.

- Consult an HVAC technician if necessary.

- Clean the thermostat regularly.

Verifying Power Supply Connections

When troubleshooting issues with your condensing boiler, verifying power supply connections is a critical step. Ensure that all electrical connections are secure and free of corrosion. A disrupted power supply can lead to insufficient energy transfer, causing your boiler to fail in producing heat or hot water.

Inspect your air filter as well, as a clogged filter can hinder airflow and affect the efficiency of your system. A dirty air filter may not only lead to heating issues but can also create conditions for dangerous situations like carbon monoxide leaks. Replacing or cleaning the air filter regularly promotes efficient energy use and extends the life of your boiler.

If you suspect power issues, check for any gas leaks that could affect your boiler's operation. Gas leaks are serious and should be addressed immediately by a professional. After confirming the power supply, it may be wise to consult with an HVAC technician for further evaluation to ensure your condensing boiler operates safely and efficiently:

- Inspect all electrical connections for security.

- Check the air filter for clogs or damage.

- Look for any indicators of gas leaks.

- Consult an HVAC technician if necessary.

Checking the Pilot Light or Ignition System

Checking the pilot light or ignition system is crucial when you encounter issues with your boiler, particularly if you experience no heat or hot water. A pilot light that has gone out can prevent your system from igniting, leading to discomfort in your home. If the flame is continuously blowing out, it’s essential to inspect for common causes like drafts or faulty thermocouples that may affect system function.

In addition, if your boiler uses a relay for ignition, ensuring it is in good condition is part of effective troubleshooting. Corrosion or damage to electrical connections may inhibit proper operation, preventing the pilot from lighting consistently. Addressing these issues not only helps restore your boiler's functionality but also increases the longevity of the system, allowing it to perform at its best.

After checking the pilot light and validating the relay's condition, you also want to ensure your tank is free from sediment buildup. Regularly flushing the tank can help maintain efficiency by avoiding blockages that could hinder heating. Take these steps to ensure your boiler system operates properly, helping you avoid future issues and ensuring your home remains warm and comfortable:

- Inspect the pilot light for proper ignition.

- Check the relay for any signs of corrosion.

- Ensure the tank is clear of sediment buildup.

- Consult with a professional if issues persist.

Examining the Pressure Gauge

Examining the pressure gauge is an essential step when troubleshooting your boiler for issues related to no heat or hot water. The pressure gauge indicates the pressure levels within the system, which is critical for proper boiler operation. If the gauge shows low readings, typically below 1 bar, it implies that the system has lost pressure, possibly due to leaks or air trapped within the system.

Conversely, if the pressure gauge indicates too high a level, often exceeding the recommended range, it might signal a malfunctioning pressure relief valve. A malfunctioning valve can lead to dangerous conditions, resulting in pressure-related furnace issues. Regular boiler maintenance includes checking these pressure levels to ensure the safe and effective operation of your heating system.

Taking action when you notice irregularities in the pressure gauge is vital. Start by inspecting the power supply connections to ensure everything is secure and functioning correctly. If issues persist, consulting with a professional can help address underlying problems with the valve and ensure your boiler runs efficiently:

- Monitor the pressure gauge for low or high readings.

- Check the functionality of the pressure relief valve.

- Inspect the power supply connections for security.

- Schedule regular boiler maintenance to prevent issues.

- Consult a professional for persistent gauge problems.

Resolving boiler Leaks and Drips

To effectively address boiler leaks and drips, start by locating the source of the leak, which may stem from loose fittings or faulty components. Tightening these fittings and valves can provide a quick fix. Additionally, replacing worn seals or sensors often prevents further leakage. These practical steps will guide you through essential boiler repair processes to restore your HVAC system's efficiency.

Locating the Source of the Leak

To effectively locate the source of a leak in your boiler, start by inspecting the area around the boiler unit. Check for visible signs of water pooling on the floor or moisture on the walls. Common furnace issues, such as loose fittings or worn-out seals, can often lead to leaks, and they can be easily identified through a thorough visual examination.

Next, pay close attention to the pipes and connections leading to and from the boiler. Any leaks at these points can compromise the efficiency of your heating system. If you notice any wetness or corrosion around the fittings, that could indicate a source of the leak, preventing potential risks like a boiler explosion.

After narrowing down the potential leak sources, consider checking the pressure gauge and pilot light as these can influence the overall operation. If the pressure is too low, it might contribute to issues affecting room temperature and comfort levels. Addressing these elements ensures that you keep your heating system efficient and safe for your home:

- Inspect the boiler for visible signs of water.

- Check pipes and connections for leaks and corrosion.

- Verify the pressure gauge and pilot light functionality.

Tightening Loose Fittings and Valves

When dealing with boiler leaks, one of the simplest and most effective solutions is to tighten any loose fittings and valves. These components can often be the source of water leaks, especially where pipes connect to radiators or the boiler unit itself. Regularly inspecting these connections can save you from more significant issues down the line, as even a small leak can lead to increased water damage and costly repairs.

Using a wrench, carefully tighten any fittings that appear loose. Be cautious not to over-tighten, as this can damage the fittings and lead to further complications. If you notice ongoing leaks after tightening, it might be necessary to replace worn washers or seals, which are readily available as HVAC parts. This proactive approach not only resolves leaks but also ensures that your Radiant Heating and Cooling system operates efficiently.

Incorporating routine checks of these connections into your maintenance plan will enhance the longevity of your boiler. Maintaining tight fittings helps optimize your HVAC supplies, ensuring that heat is effectively circulated throughout your home. By addressing these minor issues promptly, you can prevent more significant system failures and enjoy a consistently warm environment during the colder months.

Replacing Worn Seals or Components

Replacing worn seals or components in your boiler is essential for preventing leaks and maintaining efficiency. Over time, seals can become brittle and deteriorate, leading to water dripping from joints or connections. By regularly inspecting these areas, you can identify any wear and address it before it results in significant water damage or costly repairs.

To replace a worn seal, start by shutting down the boiler and allowing it to cool. Once it's safe, remove the faulty component carefully and take it to your local hardware store to find an exact replacement. Installing a new seal not only prevents leaks but also ensures your system operates at optimal performance, reducing energy costs and improving overall efficiency.

It’s important to consider the quality of replacement parts when addressing leaks in your boiler. Investing in high-quality components ensures longevity and reliability in your system. Consult with a professional if you’re unsure about the replacement process or need guidance on selecting the right parts to ensure your boiler runs smoothly and safely.

Eliminating Unusual boiler Noises

Identifying common boiler sounds can help you troubleshoot issues before they escalate. You may encounter noises like banging or hissing, which often indicate trapped air or limescale build-up in your system. This section covers practical steps for removing air from your boiler and addressing limescale and mineral deposits, ensuring your heating system operates efficiently and quietly.

Identifying Common Boiler Sounds

Understanding the sounds your boiler makes is crucial for effective troubleshooting. Common noises you may encounter include banging, which often signals trapped air in the system, or hissing that can indicate water leaks. Recognizing these sounds early can help you avoid more significant problems and maintain a comfortable environment in your home.

If your boiler is producing a rumbling sound, this may suggest that limescale buildup is affecting the heat exchanger. This accumulation can lead to inefficiencies in your boiler's operation and may require flushing the system to restore optimal performance. Addressing this issue swiftly can prevent further complications and improve your system’s heating efficiency.

Additionally, if you notice a consistent buzzing noise, it could mean there are electrical issues or that the pressure is too high. These conditions can compromise your boiler's functionality and safety. By responding to unusual sounds promptly, you can ensure your boiler remains operational and prevents unnecessary energy costs or risks to your home.

Removing Air From the System

Removing air from your boiler system is essential for optimal performance and efficiency. Air trapped in the system can create annoying noises, such as banging or gurgling, and can reduce heat circulation. Start by locating your boiler's bleed valves, usually found on radiators, to release air and ensure smooth operation.

To effectively bleed your radiators, you will need a radiator key or a flathead screwdriver. Turn the valve slowly counterclockwise until you hear a hissing sound, which indicates air release. Once water begins to flow steadily, close the valve by turning it clockwise. This process helps to eliminate trapped air and enhances the overall efficiency of your heating system.

Regularly checking and bleeding your radiators contributes to maintaining a quiet and effective boiler system. If you find that you need to bleed your system frequently, it may indicate a larger issue such as a leak or poor pressure regulation. Addressing these concerns promptly will keep your home comfortable and prevent future complications:

- Locate the bleed valves on your radiators.

- Use a radiator key to release the trapped air.

- Monitor the system for recurring air issues.

- Consult a professional if problems persist.

Addressing Limescale and Mineral Build-Up

Limescale and mineral buildup can significantly affect your boiler's efficiency and operation, often leading to unusual noises like banging or rumbling. To tackle this issue, you should consider flushing your boiler system to remove these deposits. If you live in an area with hard water, regular flushing helps maintain optimal performance and prevents costly repairs down the line.

Utilizing a descaling agent specifically designed for boilers can effectively dissolve mineral buildup. Follow the manufacturer's instructions carefully to ensure you apply the product safely and effectively. This process not only restores quiet operation but also enhances the overall efficiency of your heating system, allowing for consistent warmth throughout your home.

If you encounter persistent noises after addressing limescale, it may be time to consult a professional technician. They can perform a thorough inspection to identify and resolve underlying issues that may not be apparent. Regular maintenance, including the removal of limescale, ensures that your boiler operates smoothly, keeping your home comfortable while avoiding unnecessary disruptions.

Fixing Radiators That Won’t Heat Up

If your radiators aren't heating up, there are a few essential troubleshooting steps you can take. First, bleeding air from the radiators is crucial to remove trapped air that inhibits heat transfer. Next, balancing the heating system ensures consistent warmth across all radiators. Lastly, clearing blocked pipes or valves can restore proper flow, enhancing your boiler's efficiency and overall heating performance.

Bleeding Air From Radiators

Bleeding air from radiators is a vital step to ensure they heat up effectively. When air gets trapped in the radiator, it creates pockets that prevent hot water from circulating properly. This can lead to cold spots and overall insufficient heating performance, making your home uncomfortable during colder months.

To bleed a radiator, you'll need a radiator key or a flathead screwdriver. Locate the bleed valve, usually situated at the top of the radiator, and turn it slowly counterclockwise. You will hear a hissing sound as the trapped air releases; once a steady stream of water flows out, close the valve by turning it clockwise.

Regularly bleeding your radiators can significantly improve your heating system's efficiency and maintain even warmth throughout your home. If you find that your radiators require bleeding frequently, it may indicate a larger issue, such as a leak or inadequate pressure in the system. Addressing these concerns quickly can prevent future heating inefficiencies.

Balancing the Heating System

To achieve balanced heating throughout your home, you need to adjust each radiator to ensure it receives an adequate flow of hot water. If certain radiators aren’t heating up, it often indicates that hot water is not circulating effectively. This adjustment process can significantly enhance your boiler's efficiency and ensure that rooms maintain a consistent temperature, providing comfort during colder months.

Start by identifying which radiators are cooler than the others. You can use the radiator valves to regulate the flow of hot water; simply open the valves fully on those that are not heating up. By balancing the system in this way, you allow more hot water to reach these radiators while also preventing overheating in areas that are already warm, leading to a more efficient overall heating system.

Regularly balancing your heating system can prevent future issues where radiators fail to heat properly. It reinforces proper circulation within your boiler system, making it easier for your unit to operate as intended. If you notice ongoing difficulties despite your efforts, consulting a professional may be necessary to investigate any underlying issues within your heating setup that could be affecting performance.

Clearing Blocked Pipes or Valves

Blocked pipes or valves can lead to uneven heating in your home, causing some radiators to remain cold. To address this, start by inspecting the visible pipes connected to your radiators for any signs of obstructions or buildup. If you notice debris, cleaning the pipes may improve the flow of hot water and restore proper heating performance.

Next, ensure the valves on all your radiators are fully open. Sometimes, valves become partially closed, restricting the hot water flow, which can cause specific radiators to heat unevenly. Adjusting these valves to the open position often resolves heating issues by allowing maximum water flow through the radiator system.

If you continue to experience heating problems even after clearing blockages and adjusting valves, you may need to consult a professional. An HVAC technician can inspect the entire boiler system for hidden issues, such as deeply embedded blockages, that may hinder effective hot water circulation. By addressing this proactively, you ensure that all radiators achieve consistent warmth and maintain your home’s comfort during colder months.

Dealing With Frozen Condensate Pipes

Recognizing signs of frozen condensate pipes is essential for maintaining your boiler's functionality during winter months. If you notice your system is experiencing operational issues, you’ll learn how to safely thaw the pipe to restore flow. Additionally, implementing proper insulation techniques can prevent future freezes, ensuring your boiler operates efficiently in cold weather.

Recognizing Signs of a Frozen Pipe

To recognize signs of a frozen condensate pipe, start by observing the behavior of your boiler system. A common indication includes your boiler shutting off unexpectedly or displaying a fault code, which might suggest a blockage in the condensate system. If you notice that your heating is inconsistent or completely absent, it may indicate that the condensate flow is restricted due to freezing.

Another sign to look for is the presence of ice or frost around the condensate pipe's external section. These pipes are typically routed outside your home, making them vulnerable to freezing temperatures. If you spot any visible ice buildup, it’s a strong indicator that the pipe may be frozen, affecting your boiler's performance.

Additionally, listen for unusual sounds coming from the boiler unit. Gurgling or bubbling noises might suggest that water is unable to flow through the system freely, often due to a frozen condensate pipe. This symptom can assist in troubleshooting and addressing potential issues before they escalate:

- Observe boiler behavior for shutdowns or alerts.

- Check for ice or frost on the condensate pipe outside.

- Listen for gurgling noises indicating a blockage.

Safely Thawing the Pipe

To safely thaw frozen condensate pipes, start by turning off your boiler system. This prevents any potential damage or malfunction while you address the issue. Once the system is off, you can proceed to inspect the condensate pipe for visible frost or ice buildup, which indicates where the blockage may be occurring.

Using a warm, damp cloth or a heating pad, gently apply heat to the frozen areas of the pipe. Avoid using direct heat sources such as a blowtorch, as this can cause the pipe material to expand or crack, leading to further complications. If the ice does not begin to melt after applying warmth, you may need to rely on a hairdryer set on a low setting to help thaw the obstruction.

After successfully thawing the pipe, ensure that the area is adequately insulated to prevent future freezes. Wrapping the condensate pipe in insulation material can help maintain temperature and prevent ice buildup during colder months. Stay proactive about checking for recurring freezing issues to ensure your boiler runs efficiently throughout the winter:

- Turn off your boiler before starting the thawing process.

- Gently apply warmth to the frozen sections of the pipe.

- Avoid direct heat sources and opt for gentler methods.

- Insulate pipes to prevent future freezing problems.

Preventing Future Freezes With Insulation

To prevent future freezes in your boiler’s condensate pipes, proper insulation is essential. By wrapping the pipes in insulation material, you maintain higher temperatures, reducing the risk of ice formation even in extremely cold weather. Ensure you use materials specifically designed for plumbing to provide effective thermal resistance.

Additionally, focus on areas where the condensate pipes are exposed to outdoor temperatures. You may find it beneficial to insulate not only the pipes but also any joints or fittings. This step can help you avoid potential leaks or breaks caused by thermal contraction and expansion, keeping your heating system functioning efficiently.

Regularly inspecting your insulation can also help mitigate freezing risks. If you notice any damage or deterioration, replace the insulation promptly to maintain a protective barrier against the cold. By taking these proactive measures, you enhance the reliability of your boiler system and ensure consistent heating during winter months.

Conclusion

An easy boiler troubleshooting guide is essential for maintaining your heating system’s efficiency and safety. By understanding common issues such as leaks, unusual noises, and heating inconsistencies, you empower yourself to address problems proactively before they escalate. Regular inspection and simple checks, like verifying thermostat settings or bleeding radiators, can significantly enhance your boiler's performance and lifespan. Take control of your home’s comfort by implementing these actionable insights to ensure a warm and reliable heating system throughout the colder months.

Resources:

Learn about HVAC

Learn about boilers