When was the last time you thought about your boiler during the summer? Many assume that once the heating season ends, their boiler can be forgotten. However, improper summer shutdown can lead to efficiency issues when the cold weather returns. This post covers essential boiler maintenance tips to ensure your heating system stays in top shape. You’ll learn how to inspect your boiler, clean the combustion components, and properly shut it down, preventing costly heating system repairs later. By following these tips, you'll safeguard your equipment and enhance its longevity.

Inspecting Your Boiler Before Summer Shutdown

Before shutting down your boiler for the summer, it’s essential to conduct a thorough inspection. Look for signs of wear and damage, including checks on the gaskets and seals. Inspect for leaks and corrosion Radiant Heating and Cooling to prevent future issues. Additionally, ensure that safety valves and controls are functional to maintain a safe environment for your home or business.

Look for Signs of Wear and Damage

As you prepare to shut down your boiler for the summer, it’s crucial to look for signs of wear and damage that could lead to future issues. Pay close attention to the presence of soot around the heat exchanger, which can indicate that the combustion process is not operating efficiently. Removing this soot not only promotes better performance with Radiant Heating and Cooling but also saves you from potentially costly repairs when you fire it back up in the fall with HVAC Supplies.

Next, examine the gaskets and seals for cracks or deterioration. These components play a critical role in maintaining the integrity of your boiler system. A simple visual check can prevent unwanted leaks, which can compromise the overall performance. Additionally, consider the state of any installed corrosion inhibitors, as these help protect your boiler's internals from rust and damage during its downtime.

Finally, take a moment to check the HVAC safety controls and valves. Ensure these components are functioning correctly, as they are essential for your safety and boiler efficiency. Investing time in this inspection ensures your boiler remains in good condition through the warm months, reducing the risks of damage and ensuring a smooth transition back to operation when it’s needed again.

Check for Leaks and Corrosion

During the inspection of your boiler, checking for leaks and corrosion is vital. If your system runs on oil or natural gas, even a small leak can lead to significant safety and efficiency issues. Use a vacuum to clean around the fittings and connections, making it easier to spot any signs of liquid or gas escaping, which could indicate a problem.

Corrosion can compromise your boiler's performance and reliability. Inspect all metal components for rust or discoloration, paying close attention to joints and seams. When you notice any corrosion, it’s important to address it immediately to prevent further deterioration and to maintain proper functionality for your heating system.

In addition to visible signs, consider using refrigerant dyes or leak detection tools specifically designed for HVAC systems. These tools can help you identify hidden leaks that may not be apparent during a standard inspection. By ensuring your boiler is free from leaks and corrosion, you reduce the risk of costly repairs and enhance the longevity of the equipment.

Ensure Safety Valves and Controls Are Functional

Ensuring that safety valves and controls are functional is a critical step in preparing your boiler for summer shutdown. Check the safety valve to confirm it is free from any debris that could hinder its operation. This valve is essential for releasing excess pressure, preventing dangerous situations that could lead to equipment failure or even carbon monoxide leaks.

Assess the operation of the pumps, as they are integral to maintaining flow and pressure in your boiler system. A malfunctioning pump can disrupt water circulation, potentially leading to overheating and increasing the risk of carbon dioxide buildup in the flue. Regular maintenance ensures these components operate efficiently, promoting a safe and reliable system.

Lastly, take time to inspect any control panels associated with your boiler. Functional controls are necessary for monitoring and adjusting system performance. This can help effectively manage scenarios that could lead to hazardous situations, ensuring a safe working environment. By prioritizing the inspection of safety valves and controls, you set the stage for a trouble-free boiler reactivation come fall:

- Clear debris from safety valves

- Check and service pumps

- Inspect control panels for functionality

Essential Cleaning Steps for Boiler Maintenance

Cleaning your boiler is vital for its longevity and efficiency. Start by removing soot from heat exchange surfaces to enhance heat transfer. Next, clean the combustion chamber to prevent buildup that can affect water heating performance. Finally, ensure to clear debris from burners and ignitors, facilitating optimal operation in your central heating system. These essential steps protect your pressure vessel and improve overall efficiency.

Remove Soot From Heat Exchange Surfaces

Removing soot from the heat exchange surfaces of your boiler is a crucial maintenance step that enhances efficiency and prolongs equipment life. Soot accumulation can act as an insulating barrier, hindering heat transfer and leading to increased carbon production during combustion. By prioritizing this task, you ensure that your boiler operates optimally, ultimately saving on energy costs in your commercial HVAC system.

Begin by carefully cleaning the heat exchange surfaces with appropriate tools, such as a vacuum or soft brush, to avoid damage. Regular maintenance will facilitate drainage during the heating season, preventing soot buildup that can impede performance. Keeping these areas clean not only enhances your boiler's efficiency but also helps maintain safer operational standards, reducing the risk of hazardous conditions.

After you have removed the soot, take a moment to inspect the tank and hydronics associated with your boiler. Addressing potential issues promptly can prevent minor concerns from escalating into costly repairs. A well-maintained system allows you to enjoy dependable heating year after year, providing comfort and peace of mind as the cooler months approach:

- Ensure thorough cleaning of heat exchange surfaces.

- Use appropriate tools for effective soot removal.

- Inspect the tank and hydronics after cleaning.

Clean the Combustion Chamber

Cleaning the combustion chamber is an essential step in maintaining your boiler during summer shutdown. A clean combustion chamber not only boosts efficiency but also contributes to better indoor air quality by preventing the buildup of harmful byproducts. Over time, soot and debris can accumulate, impacting the overall performance of your heating system, so it’s crucial to address this area promptly.

When cleaning the combustion chamber, you should first turn off the boiler and let it cool completely. After ensuring safety, carefully remove any carbon buildup using appropriate cleaning tools. Pay particular attention to the steel surfaces within the chamber, as these may corrode if not properly maintained. Regular cleaning will help prevent costly repairs due to corrosion or potential flooding from water backups.

Remember to inspect the relief valve during your maintenance routine. This valve plays a critical role in ensuring your system operates safely by releasing excess pressure, which can be especially important during air conditioning season. By keeping the combustion chamber clean and the relief valve functioning properly, you create a safer and more efficient heating environment for your home or business:

- Turn off the boiler and allow it to cool.

- Carefully remove soot and debris from the combustion chamber.

- Inspect steel surfaces for corrosion and clean them as needed.

- Check the relief valve for proper functioning.

Clear Debris From Burners and Ignitors

Clearing debris from burners and ignitors is a crucial maintenance step that directly impacts your heating system’s efficiency. Accumulated dust, soot, or other particles can obstruct airflow, leading to incomplete combustion and potential overheating. As you prepare for summer shutdown, taking the time to clean these components helps to reduce the risk of corrosion and ensures that your system is ready for a smooth restart when cooler weather returns.

During the cleaning process, it’s essential to examine the condition of the safety valve, as it plays a key role in your boiler’s operation. Make sure there is no debris around the safety valve, which could hinder its performance and lead to dangerous pressure build-up. By maintaining a clean area around the ignitor and burner, you not only ensure efficiency but also support the safe operation of your entire system.

Don’t forget to check the chimney as well; a clean chimney contributes to optimal exhaust flow. If debris accumulates, it can restrict venting and result in potential backdrafts, affecting both efficiency and safety. Properly clearing debris from all relevant components protects against operational issues, allowing your heating system to perform effectively while minimizing the risk of unexpected repairs down the line.

Proper Procedures for Shutting Down Your Boiler

To ensure a safe and effective boiler shutdown for the summer, it's essential to follow proper procedures. Start by gradually reducing the temperature and pressure to prevent thermal shock. Adhering to the manufacturer's shutdown guidelines will enhance safety and efficiency. Lastly, secure fuel and electrical sources to eliminate the risk of leaks and moisture, which can affect boiler water quality and require water treatment for optimal performance.

Gradually Reduce Temperature and Pressure

To initiate a proper boiler shutdown, you should gradually reduce the temperature and pressure in your system. This approach helps to prevent thermal shock, which can cause pipes to crack or other components to fail. By slowly lowering the thermostat setting, you facilitate a smoother transition, allowing your boiler to cool down without risking damage.

During this process, keep an eye on the pressure gauge to ensure it remains within safe limits. If you notice any sudden drops or rises, make adjustments to your air conditioning maintenance routine accordingly. Additionally, it could be helpful to create a checklist that includes monitoring temperature and pressure as you prepare for the summer shutdown.

Once you have successfully reduced the temperature and pressure, make sure to drain the boiler as per manufacturer guidelines. A well-executed drain will remove any residual water that may become stagnant and lead to corrosion over time. Follow these steps to ensure your boiler is properly prepared for a summer recess and remains in optimal condition for future use:

- Lower the thermostat setting gradually.

- Monitor the pressure gauge consistently.

- Create a shutdown checklist for reference.

- Drain the boiler according to guidelines.

Follow Manufacturer's Shutdown Guidelines

Following your manufacturer's shutdown guidelines is essential for effective boiler maintenance. Each boiler model has specific requirements that ensure safe operation and long-term reliability. By adhering to these guidelines, you minimize risks and ensure that your heating system maintenance aligns with industry standards, promoting a smooth transition into the summer months.

Take the time to familiarize yourself with the owner's manual, as it contains valuable instructions specific to your boiler type. Following these procedures helps you avoid potential issues, such as pressure fluctuations, which can stress your system. Ensuring proper shutdown and maintenance, as recommended, prepares your boiler for future operation and maintains an optimal atmosphere for your home or business.

Moreover, consider scheduling an inspection with a qualified technician if you're unsure about the shutdown process. Their expertise can aid in implementing the manufacturer’s recommendations and support your cooling tower or heating system's overall functionality. Investing in professional assistance ensures that every aspect of your boiler's shutdown aligns with best practices, safeguarding its performance when it's time to start it up again.

Secure Fuel and Electrical Sources

Securing fuel and electrical sources is a critical part of shutting down your boiler for the summer season. Begin by turning off the gas supply by closing the valve that leads to your furnace. This step is vital to prevent any potential leaks or safety hazards, particularly since the pilot light should remain off during the summer, ensuring no unnecessary fuel consumption.

Next, it's important to disconnect or switch off the electrical supply to your boiler. This action not only stops the operation of the system but also protects sensitive components from voltage spikes during the downtime. Make sure to monitor any indicators, such as the sight glass, to ensure there are no remaining flames or active signals before fully securing these connections.

Finally, after addressing the fuel and electrical sources, check to ensure there is adequate oxygen ventilation in the area where your boiler is located. Proper ventilation helps maintain air quality and helps prevent potential issues when you reactivate the system in the fall. By taking these precautionary measures, you create a safer environment around your boiler and prepare it for a successful restart when cool weather returns.

Draining and Flushing Your Boiler System

To prepare your boiler for summer, you need to safely drain the remaining water to prevent corrosion. After draining, it’s essential to flush the system to eliminate sediment accumulation, ensuring optimal performance when you restart. Finally, inspect the internal surfaces for any wear or damage, as this helps maintain system efficiency and longevity, especially when dealing with HVAC Parts and supplies.

Safely Drain Water From the Boiler

To safely drain water from your boiler, start by turning off the system and letting it cool down completely. This step is crucial to prevent any risk of burns or injury while handling hot water and components. Once the system has cooled, locate the drain valve, which is typically found at the lowest point of the boiler, allowing for efficient water removal.

Connect a hose to the drain valve and run it to a suitable drain or container. Open the valve slowly to release the water, monitoring the flow to avoid spraying or splashing. If you experience any resistance or blockage, do not force it; instead, inspect the valve and clean any debris that may be obstructing the flow.

After the water has been fully drained, close the valve securely to prevent any leaks. Taking the time to drain your boiler properly helps combat issues related to corrosion and sediment buildup. By following these steps, you ensure your boiler is ready for the downtime of summer while promoting optimal performance when you restart it in the fall.

Flush the System to Remove Sediment

Flushing your boiler system to remove sediment is a crucial task before the summer shutdown. Over time, minerals and other debris can accumulate in the boiler, potentially leading to inefficiencies or even damage. By flushing the system, you ensure that these contaminants are cleared, promoting a cleaner and more efficient heating process when you restart your system in the fall.

To effectively flush the system, you will need to locate the drain valve typically found at the lowest point of your boiler. Attach a hose to the valve leading to a suitable drainage area. Open the valve slowly and allow the water to flow out, taking care to observe the clarity of the water; cloudy or dirty water indicates sediment buildup that needs to be addressed. Regular flushing helps to maintain a high standard of operation.

Once you have flushed the water from the system, it’s beneficial to perform a quick inspection of the internal surfaces for any corrosion or excessive wear. Observing the condition of the boiler helps you proactively address minor issues before they develop into costly repairs. Following these steps will ensure your boiler operates efficiently, providing dependable heating when needed.:

- Locate and open the drain valve to remove water.

- Monitor water clarity during the flushing process.

- Inspect the internal surfaces for wear or damage.

Inspect Internal Surfaces After Draining

Once you have drained the water from your boiler, it’s crucial to inspect the internal surfaces for any signs of wear or damage. Pay close attention to areas that may have been prone to corrosion due to prolonged exposure to water or mineral buildup. Identifying these problems early can save you from costly repairs and ensure your boiler remains efficient during the next heating season.

While inspecting, look for rust or pitting on the metal surfaces, as these can compromise the integrity of your boiler system. If you notice significant corrosion, it may be time to consider replacing components or applying protective coatings. Regular inspections, coupled with proper maintenance practices, enhance the longevity and reliability of your heating system, keeping you warm and comfortable when the cold months return.

Additionally, take this opportunity to ensure that all connections and fittings are secure and free of debris. Loose connections can lead to leaks when the boiler is back in operation, while debris can restrict proper functioning. By maintaining vigilance during your inspection, you not only promote the safety of your system but also support optimal performance when it’s time to reactivate your boiler.

Protecting Your Boiler During the Summer Season

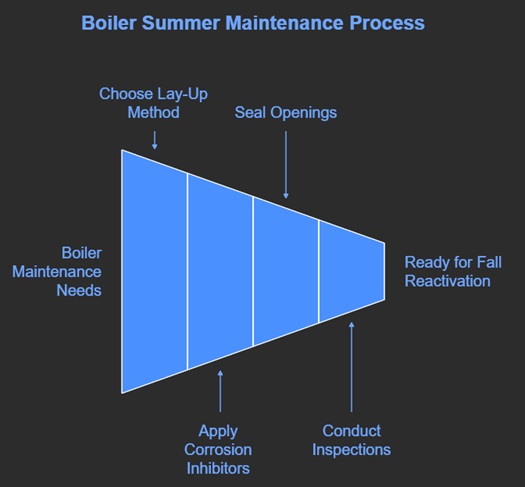

To ensure your boiler remains in good condition during the summer season, apply wet or dry lay-up methods to protect it from potential damage. Consider using corrosion inhibitors, if necessary, to safeguard metal components. Additionally, sealing openings will prevent contaminants from entering, which could impact performance when you reactivate your system. These steps enhance the effectiveness of your boiler maintenance efforts.

Apply Wet or Dry Lay-Up Methods

Applying wet or dry lay-up methods is essential for protecting your boiler during the summer months. Wet lay-up involves filling the system with water and adding chemical treatments to prevent corrosion and maintain a clean environment. This method is particularly effective for boilers that remain inactive for an extended period, ensuring that metal components remain safeguarded against moisture and rust.

On the other hand, dry lay-up is suitable for shorter downtime or specific conditions where moisture may pose a risk. This method entails draining the boiler completely and then applying protective coatings to the interior surfaces. By sealing openings and eliminating residual water, you can help prevent contaminants from entering and causing damage when the system is not operational.

Regardless of the method chosen, make sure to monitor the condition of your boiler throughout the summer. Regular checks can help you identify and address any potential issues before reactivation. Consider the following steps to effectively manage your boiler's summer care:

- Select between wet or dry lay-up methods based on your boiler's needs.

- Apply corrosion inhibitors to protect metal components.

- Seal openings to prevent contaminants from entering the system.

- Conduct periodic inspections throughout the summer season.

Use Corrosion Inhibitors if Necessary

Using corrosion inhibitors is a critical step in safeguarding your boiler during the summer months. These chemicals help protect metal components from rust and degradation, which can occur due to prolonged exposure to moisture and stagnant water. By adding corrosion inhibitors to your system, you ensure that your boiler remains intact and efficient, ready for operation when the cooler weather returns.

You'll want to assess whether your boiler requires corrosion inhibitors based on its condition and the specific materials used in its construction. If your system has a history of corrosion or has been under stress due to high usage, applying these inhibitors can be especially beneficial. This preventive measure minimizes the risk of unexpected repairs, giving you peace of mind during the summer downtime.

Finally, ensure that you follow the manufacturer's recommendations regarding the type and amount of corrosion inhibitor to use. Over-treating can lead to complications, while under-treating may not provide adequate protection. By adhering to these guidelines, you not only enhance the longevity of your boiler but also optimize its performance when you're ready to reactivate the system in the fall.

Seal Openings to Prevent Contaminants

Sealing openings in your boiler is a crucial step to prevent contaminants during the summer season. By ensuring that all gaps and openings are effectively sealed, you reduce the risk of dust, debris, and moisture entering the system, which can lead to potential damage or efficiency issues when it's time to restart your boiler. Take a close look at any connections, access points, or other areas that may be susceptible to infiltration.

To seal these openings, consider using weather stripping or dedicated sealants suitable for HVAC systems. These materials create a tight barrier, ensuring that harmful elements cannot compromise the integrity of your boiler. Regularly inspect these seals during your summer maintenance check to make sure they remain intact, as wear and tear can sometimes occur over time.

By taking the necessary precautions to seal openings, you maintain a clean and efficient environment for your boiler system. Keeping contaminants out means you can expect a smoother startup in the fall, reducing the chances of repairs or performance issues. Here’s a quick summary of steps to consider:

- Identify all potential openings around your boiler.

- Use appropriate materials to create effective seals.

- Regularly inspect and maintain these seals over the summer.

Planning Maintenance Before the Next Heating Season

Planning for maintenance before the next heating season is crucial for your boiler's reliability. Schedule a professional inspection and necessary repairs to address any lingering issues. It's also important to test and calibrate controls and instruments for optimal performance. Finally, preparing your boiler for efficient startup will ensure it operates smoothly when you need it most.

Schedule Professional Inspection and Repairs

Scheduling a professional inspection and repairs for your boiler is a proactive step that ensures your heating system operates efficiently when cooler temperatures return. A qualified technician can identify issues that may not be apparent during regular maintenance, ensuring that your boiler is ready for the demands of the upcoming heating season. By addressing these potential problems early, you reduce the risk of unexpected breakdowns when you rely on your boiler the most.

During the professional inspection, the technician will check all key components, including safety valves, controls, and the combustion chamber. They can provide valuable insights into the current condition of your system and recommend any necessary repairs or updates. This detailed approach minimizes the chances of sudden failures and maximizes your boiler's efficiency, ultimately saving you money on energy costs in the long run.

Make it a priority to book your inspection well in advance of the heating season. Waiting until the first cold snap may leave you without heat if problems arise. To maintain the reliability of your heating system, consider these key takeaways for planning your boiler maintenance:

- Schedule regular professional inspections to catch issues early.

- Ensure safety valves and controls are thoroughly checked.

- Plan your appointments ahead of the heating season to avoid delays.

Test and Calibrate Controls and Instruments

Testing and calibrating the controls and instruments of your boiler is essential to ensure optimal performance when the heating season returns. Start by examining the thermostat and ensuring it accurately reflects the temperature settings. A miscalibrated thermostat can lead to inefficient heating, causing discomfort and increased energy costs. Taking the time to verify its accuracy now can save you from inconvenience later.

Next, focus on the safety controls, including pressure and temperature gauges. These instruments are crucial for maintaining the safe operation of your boiler. If you notice discrepancies in their readings, it may indicate a need for recalibration or replacement. Addressing these issues ahead of time can prevent potential hazards and ensure your boiler operates reliably throughout the winter.

Finally, consider reviewing the control system that allows you to adjust the heating output. Make sure that everything functions smoothly and responds appropriately to your adjustments. This proactive approach not only enhances system efficiency but also provides peace of mind, knowing you are prepared for the seasonal demands ahead. By dedicating time to test and calibrate your boiler's controls, you enhance its longevity and performance, ensuring a comfortable environment in your home or business.

Prepare for Efficient Boiler Startup

To prepare for an efficient boiler startup, start by ensuring that all maintenance checks are completed well before the heating season begins. This proactive approach minimizes the risk of issues arising when you need your boiler the most. A thorough inspection of key components, including safety valves, burners, and controls, will help you identify and fix potential problems early.

Another essential aspect of preparing for a smooth startup is to check and calibrate your boiler's controls, especially the thermostat and pressure gauges. Miscalibrated controls can lead to inefficient performance, wasting energy and increasing costs. When you ensure these instruments function correctly, you lay the groundwork for reliable heating throughout the winter.

Finally, documenting all inspections and maintenance activities in a checklist can help track what has been completed and what still needs attention. This organization will support your boiler's efficiency and ensure that you won't overlook any critical steps leading to a successful startup. By following these actionable insights, you can confidently start your boiler when the colder months arrive and avoid any unnecessary downtime or repairs:

- Complete all maintenance checks early.

- Inspect key components for issues.

- Check and calibrate controls accurately.

- Document all inspections in a maintenance checklist.

Conclusion

Implementing essential boiler shutdown maintenance tips for the summer season is crucial for ensuring your heating system's efficiency and longevity. By thoroughly inspecting for wear, leaks, and corrosion, you can prevent costly repairs and improve safety. Regular cleaning, draining, and proper shutdown procedures keep your boiler in peak condition, ready for operation when colder weather returns. Prioritizing these maintenance steps now not only enhances performance but also provides peace of mind throughout the summer months.

Resources:

Learn about HVAC

Learn about boilers